When conducting a vibration test, it is important to consider the various methods of mounting an accelerometer. Some methods are more reliable than others, but the test requirements may take precedence. Below, we discuss three of the most common accelerometer mounting methods.

You can also download a PDF version of this content for your laboratory.

Primary Accelerometer Mounting Methods

STUD MOUNTING

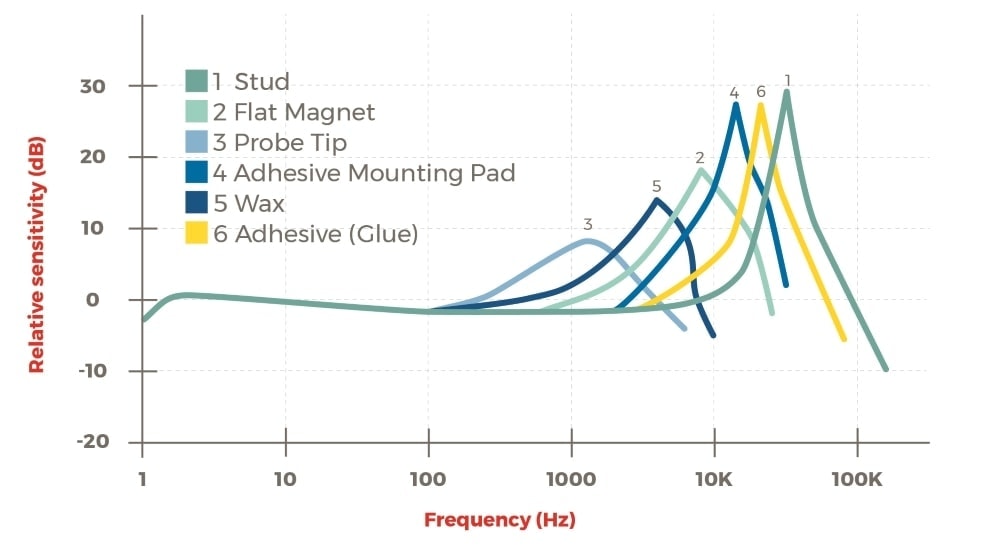

Mounting the accelerometer to the device under test (DUT) with a stud is the best method to mount an accelerometer (Figure 1). Adding a thin layer of silicon grease to the base of the accelerometer fills the microscopic pits and grooves on the surface and creates better surface contact. Stud-mounted accelerometers can measure vibration responses across a range of frequencies and exhibit high-frequency transmissibility values.

Mounting the accelerometer to the device under test (DUT) with a stud is the best method to mount an accelerometer (Figure 1). Adding a thin layer of silicon grease to the base of the accelerometer fills the microscopic pits and grooves on the surface and creates better surface contact. Stud-mounted accelerometers can measure vibration responses across a range of frequencies and exhibit high-frequency transmissibility values.

ADHESIVES MOUNTING

An adhesive method of mounting an accelerometer can be used when it is impractical to mount the accelerometer using a stud. There are several adhesives that are effective in mounting an accelerometer:

- Glue (cyanoacrylate, epoxies, and hot glue)

- Wax (Paraffin; Beeswax)

Proper preparation of all adhesives includes clean surfaces and a very thin layer of adhesive. Glue provides a better resonant frequency response than wax. Wax adhesives are dependent upon temperature, surface material, and preparation.

Both adhesive methods can obtain an excellent data response. However, cyanoacrylate glue is an instant adhesive and provides a more accurate high-frequency performance. As such, cyanoacrylate glue and is the preferred adhesive solution in most circumstances. Wax is a convenient and simple adhesive and is generally used in short-term situations. Epoxy and hot glue are convenient mounts for low-frequency testing.

MAGNETIC MOUNTING

In some situations, it may be appropriate to use a mounting method involving magnets. There are, however, some concerns with the magnetic method.

The responses from a magnetic mounting method are of poorer quality than the adhesive methods or the stud-mounted method. Additionally, mounting an accelerometer with a magnetic method is only effective if the DUT contains magnetic materials, and the magnetic attraction between the surface of the DUT and the mounting magnet is strong. The strength of the attraction between the surface of the DUT and the mounting surface is greatest when the two surfaces are in good contact. If the surface of the DUT is curved, then the magnetic attraction between the DUT surface and the mounting magnet decreases.

Mounting Orientations

It is also important to consider the orientation of the accelerometer when mounting. A single-axis accelerometer only measures data in one specific direction. For example, if the vibration of the DUT is in a horizontal plane and the accelerometer is mounted to collect data from the vertical plane, then the accelerometer will not read the correct vibration if any vibration at all. Attention to detail in this regard is important. Test engineers must be aware of the direction of the DUT’s vibration as well as the orientation of the accelerometer should be mounted to collect the vibration data from the DUT.