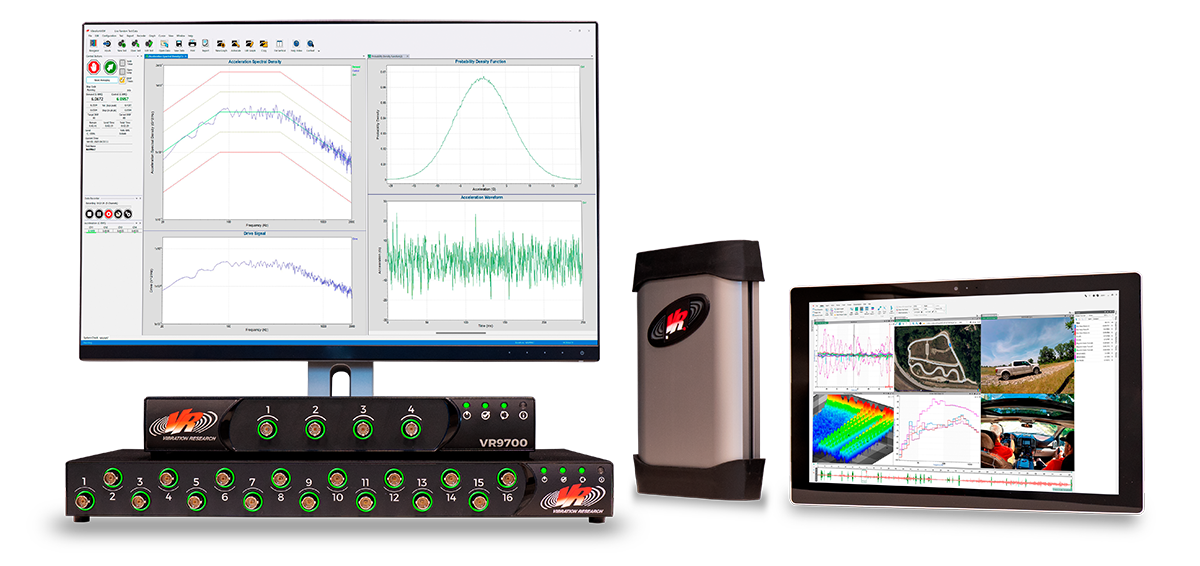

VibrationVIEW Software Package

Sine

Random

Shock

Test Acceleration

Fatigue Damage Spectrum

Transient Capture

Kurtosion

RecorderVIEW

Field Data Replication (FDR)

Fulfill Medical Packaging Test Specifications

Generate test profiles or enter specifications with ease. The VibrationVIEW interface is intuitive and user-friendly, and the software is industry-leading. Access standard vibration testing modes built for ease of use and advanced features you won’t find anywhere else.

Package Drop Shock Testing

Test a packaged item’s capability to survive a drop, hit, impact, fall, or other short-term vibration event that may occur in transit.

Define & Run a Random Test

Validate Component Durability

Fulfill test standards with random software features such as:

- Control any electrodynamic or servo-hydraulic shaker

- Frequency/amplitude breakpoint table (up to 9,999 entries)

- Easy-to-read tabular format

- Power spectral density (PSD) and probability density function (PDF) displays

Free Demo Controller & Software

Put us to the test! Whether it is a brand-new system or a replacement controller, we will let you try our fully-enabled hardware and software for 30 days. Once you use it, we think you will be hooked.

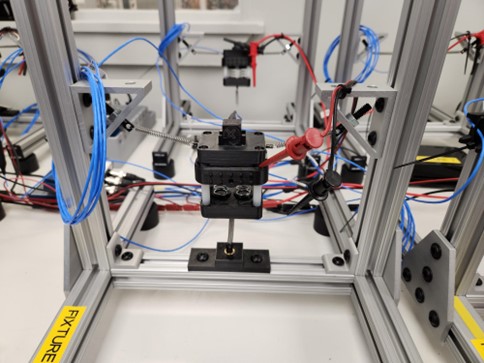

Haptic Motor Vibration Test

A VR customer ran a pass/fail test for haptic vibration motor strength. They recorded the test data using the ObserVR1000 and analyzed the test results in ObserVIEW to improve repeatability.

A VR customer ran a pass/fail test for haptic vibration motor strength. They recorded the test data using the ObserVR1000 and analyzed the test results in ObserVIEW to improve repeatability.

Create Profiles from Field Data

VibrationVIEW offers several test development methods to replicate the original environment of a product using recorded data. The result is a test profile that closely reflects—or is the equivalent to—the field environment.

Customizable Automated Reporting

With VibrationVIEW’s custom reporting options, you can define the included parameters to adhere to test standards or customer requests. Add other details such as data vectors, graphs, screen images, test notes, and company branding.