A vibration test system may generate an error or stop operating without a clear cause. The reason for the error could be a number of things: a loose connection, frayed cables, issues with the amplifier, a malfunctioning shaker, etc. In some cases, the problem derives from the controller. Although this is rare, you should make sure your controller(s) are working properly during the process of elimination.

Loopback diagnostics is a straightforward process to determine if your controller is functioning properly. It allows you to troubleshoot a vibration system by isolating the controller from the shaker/amplifier. A “loopback” runs the controller’s output to the input, thereby removing the shaker/amplifier from the system.

Loopback diagnostics is also helpful if a shaker is not behaving as expected. The controller may be sending a signal to the shaker that’s causing the issue. In this case, you can run a loopback check and compare the results to when the controller was connected to the shaker/amplifier. If the loopback results are as expected, then you know to look at the shaker/amplifier to correct the problem.

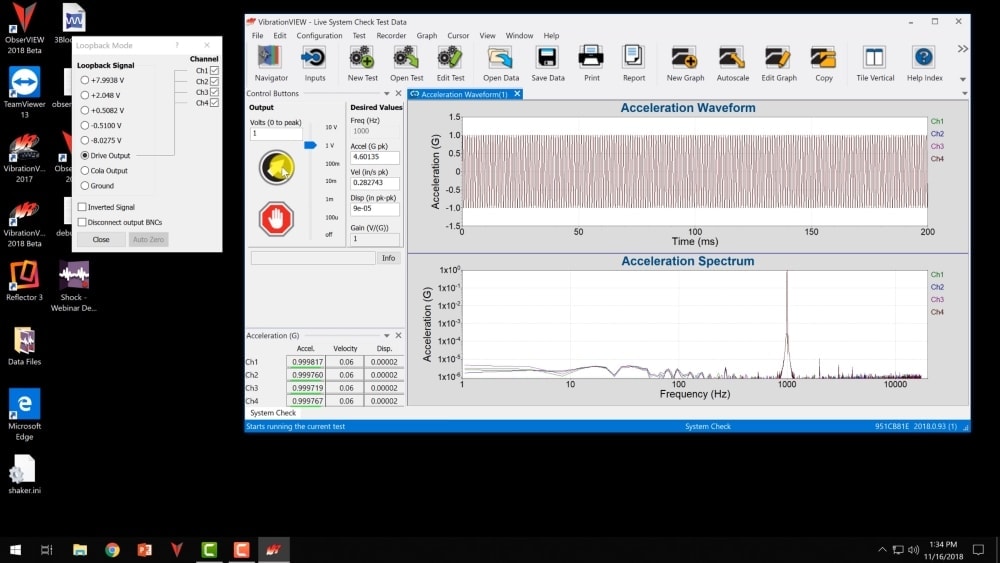

Loopback diagnostics is a tool in VibrationVIEW that allows you to verify the functionality of a VR9500/VR10500 controller. It internally connects the drive or COLA to the input channels, which eliminates the need for BNC cables or a shaker. A loopback check is usually performed during a System Check test.

For detailed instructions on setting up and running loopback diagnostics, see the video below: