Vibration Controller Systems

Compatible with all shakers

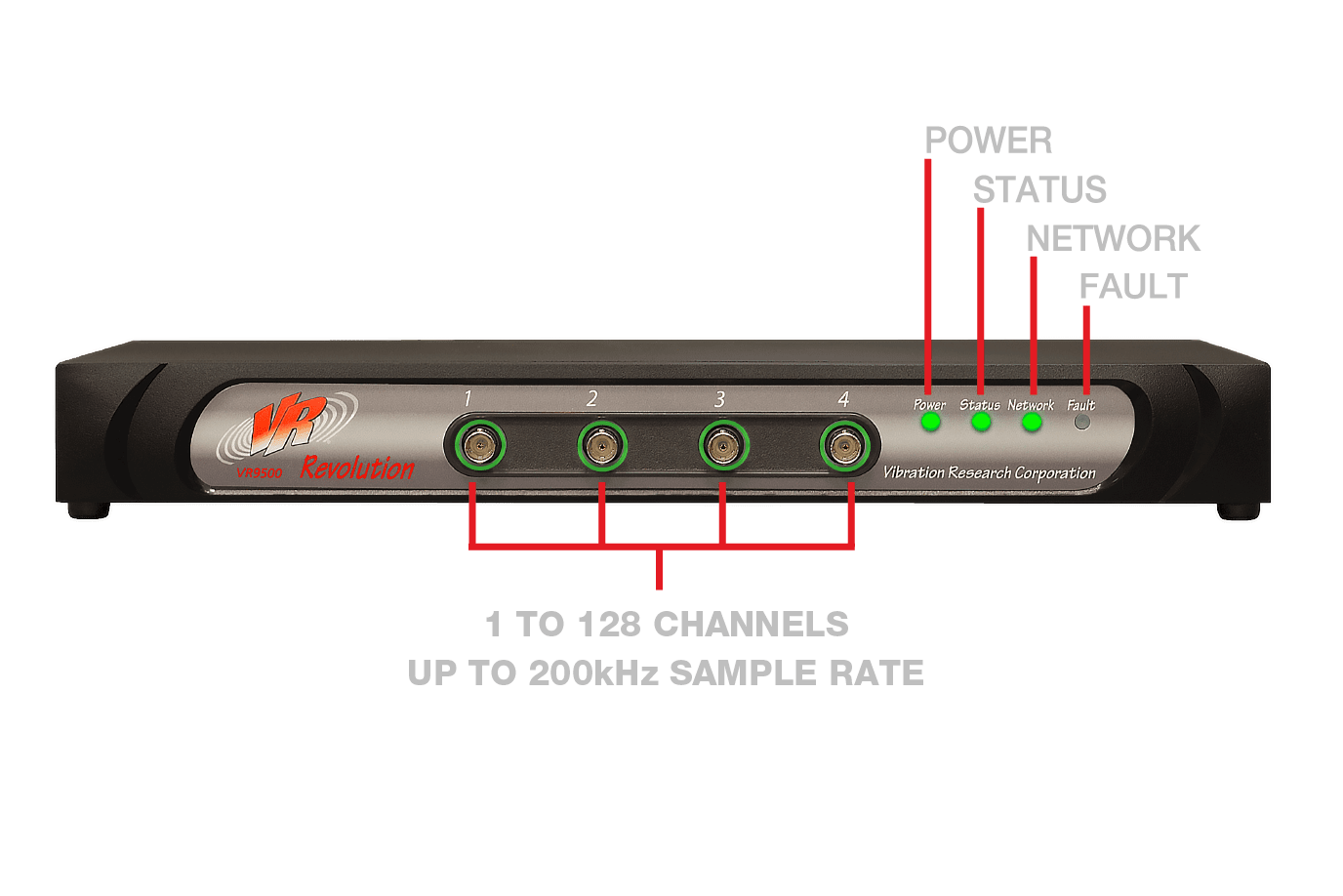

VR9500

VibrationVIEW Controller Hardware

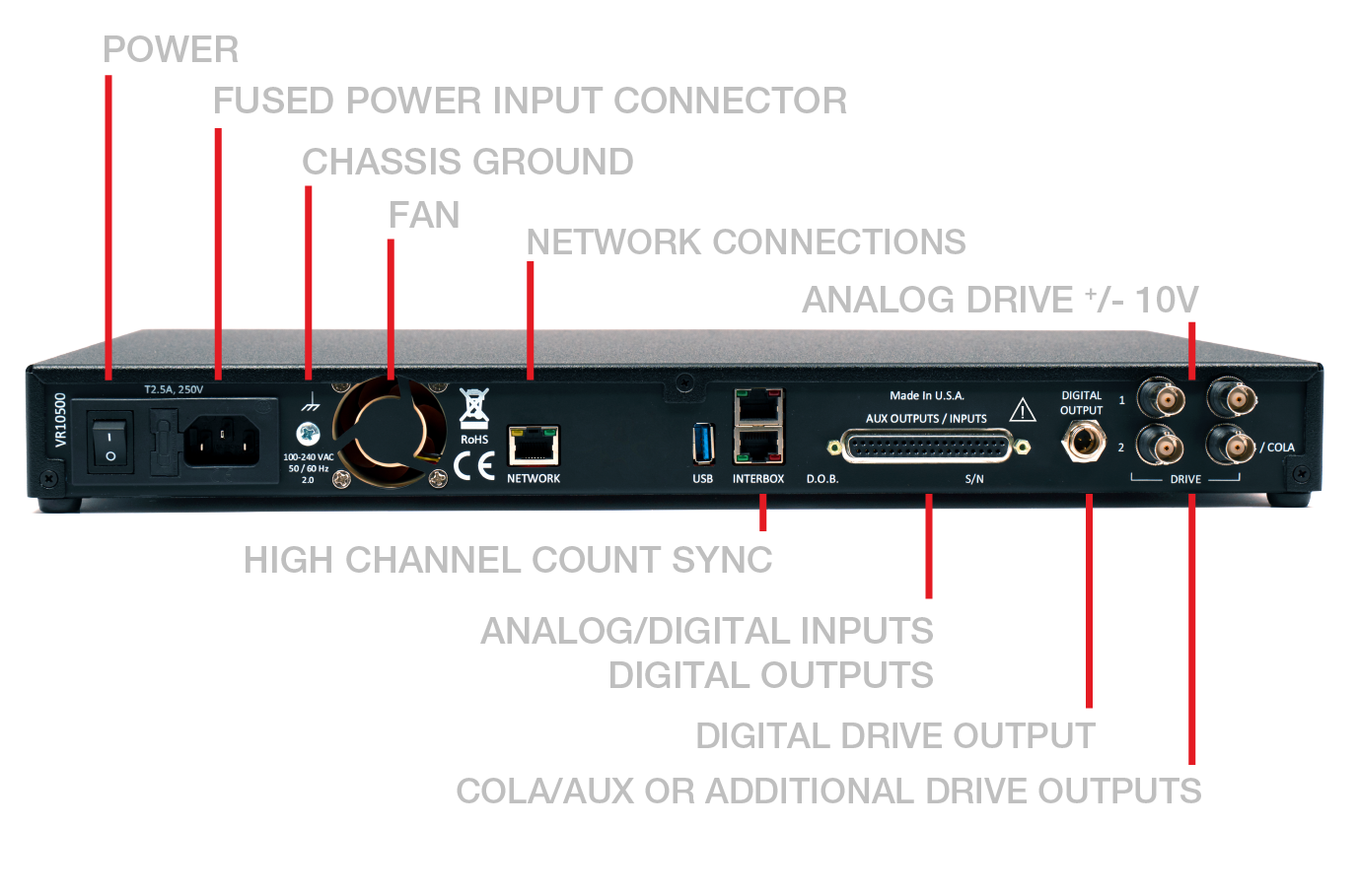

VR10500

VibrationVIEW Controller Hardware

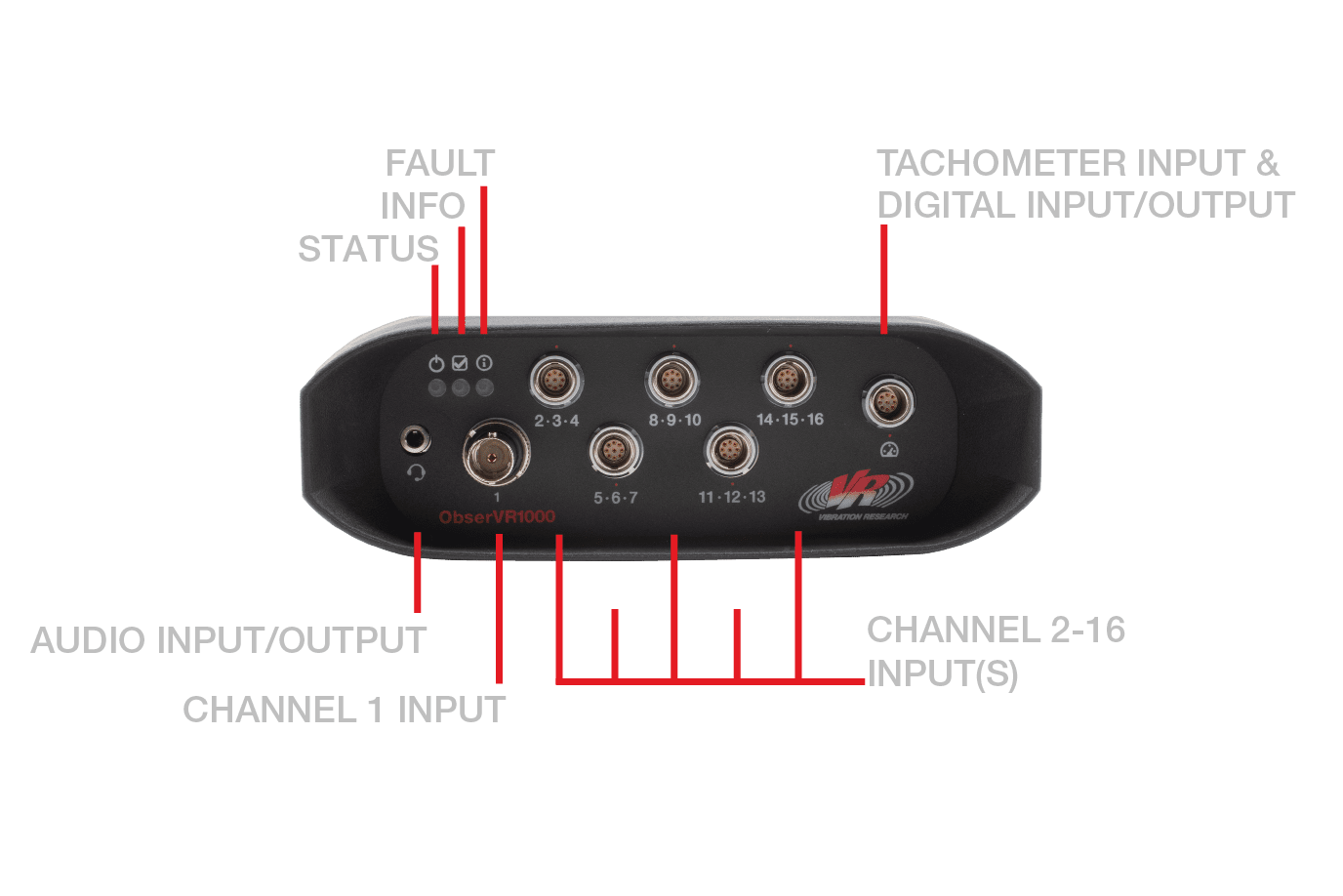

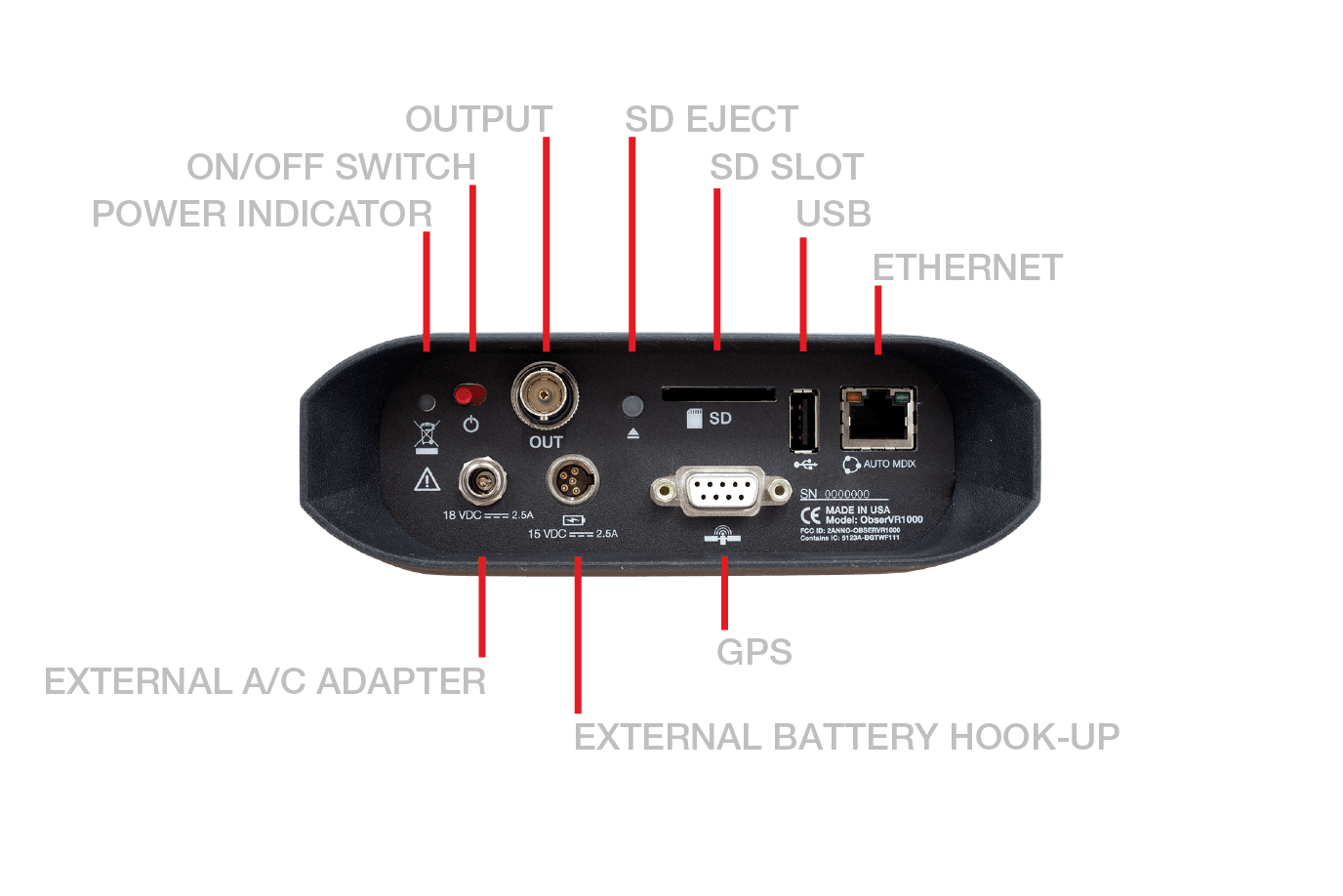

ObserVR1000

VibrationVIEW Controller Hardware

Upgrades & Support

work more efficiently, avoid risk, and save precious time

A continual U&SA renewal ensures that your controller hardware is free of defects in materials and workmanship for the unit's lifetime under warranty coverage.

A current U&SA includes an Automated Calibration Verification software license and a 50% discount on standard factory calibration or A2LA-accredited calibration.

U&SA customers stay up-to-date with new software versions released annually and minor enhancements released periodically.

Access unlimited technical support via phone, email, webinar, and more with a current U&SA.

VibrationVIEW

Set up and monitor vibration tests and customize automated reports

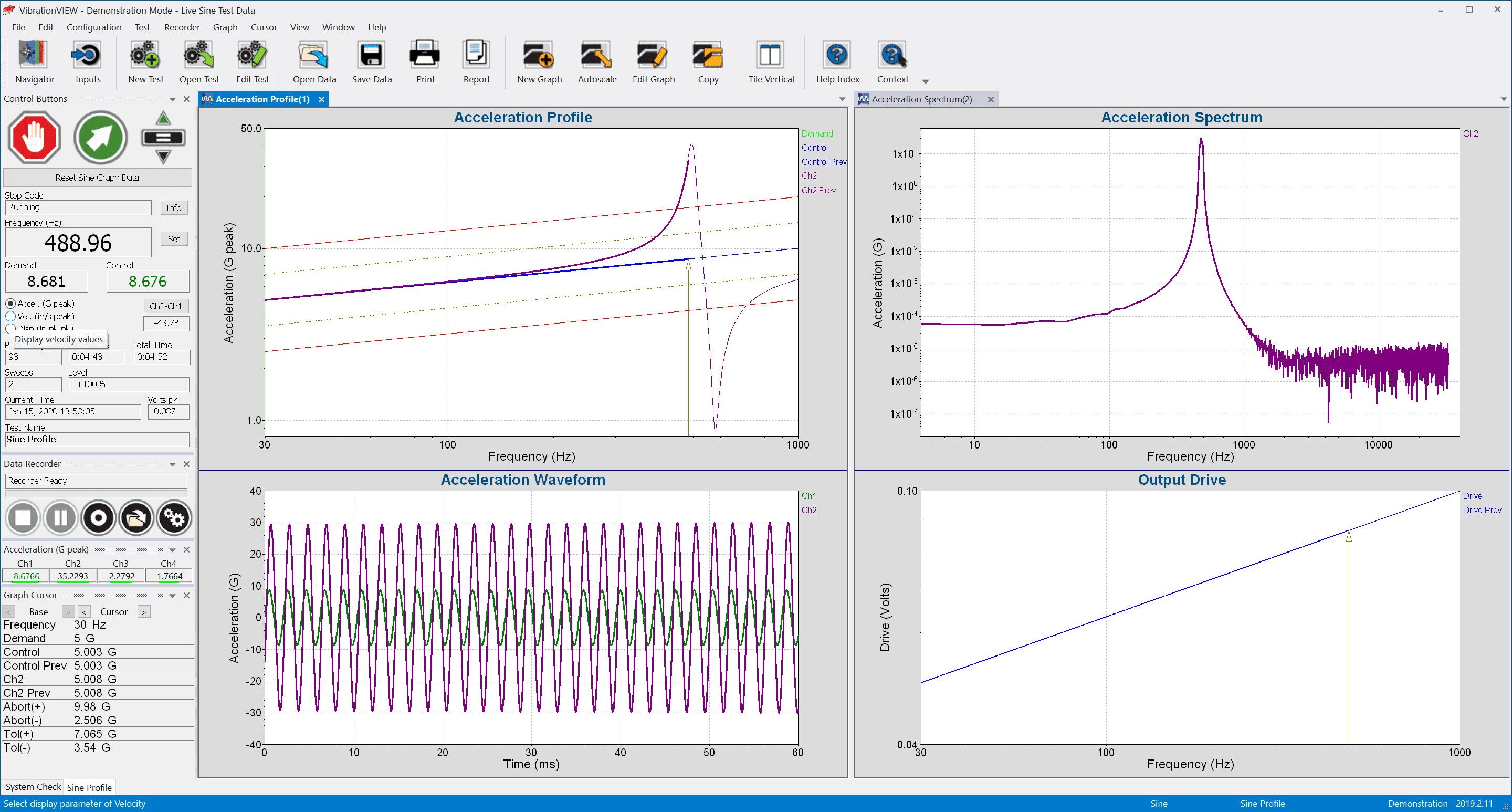

Sine

Run swept or fixed-frequency sine vibration tests with control of acceleration, velocity, or displacement.

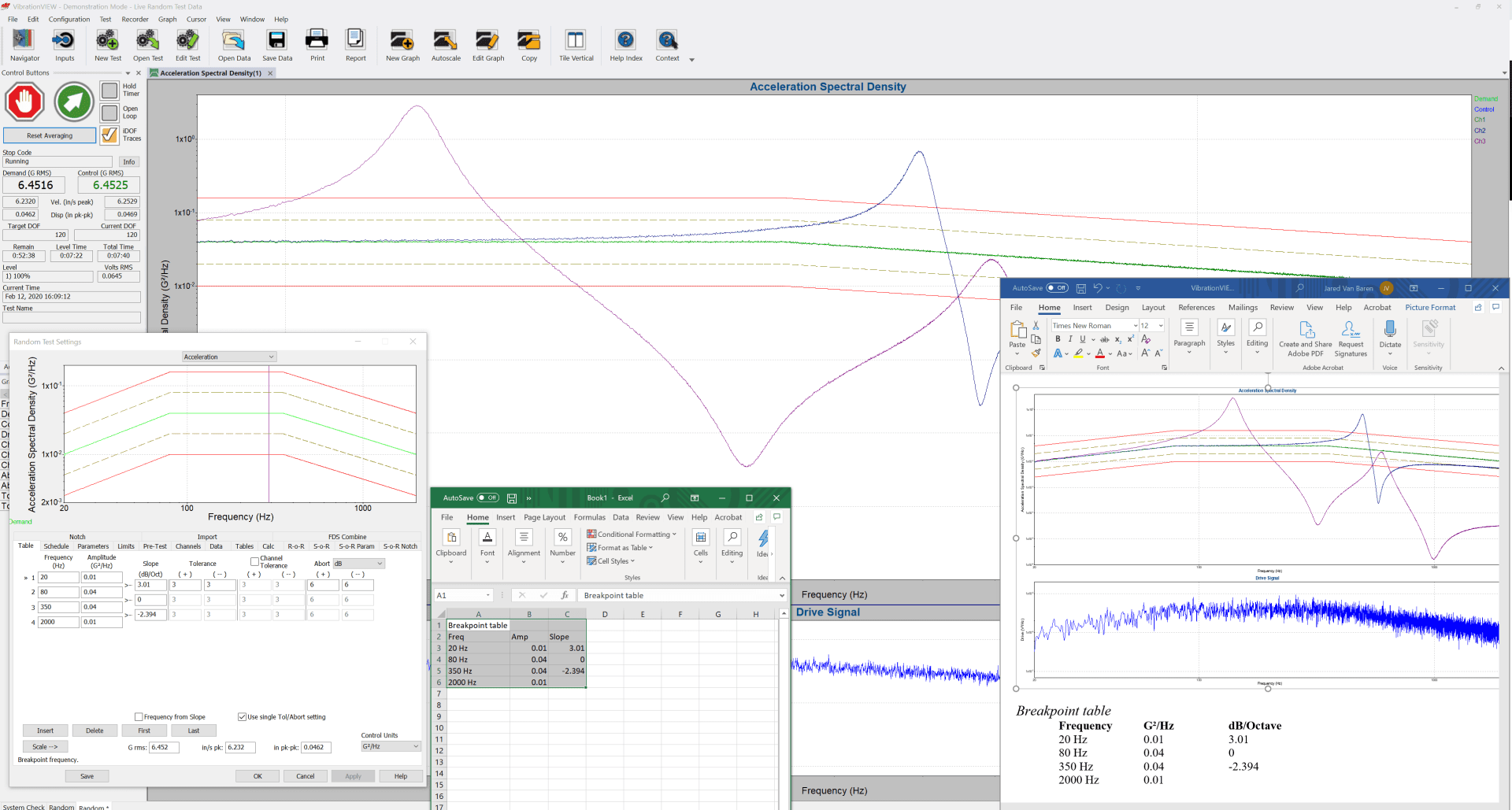

Random

Run random vibration tests with a spectral-shaped Gaussian amplitude distribution. Vibration Research's iDOF allows quick test ramp-up, tight tolerances, and easy resonance detection.

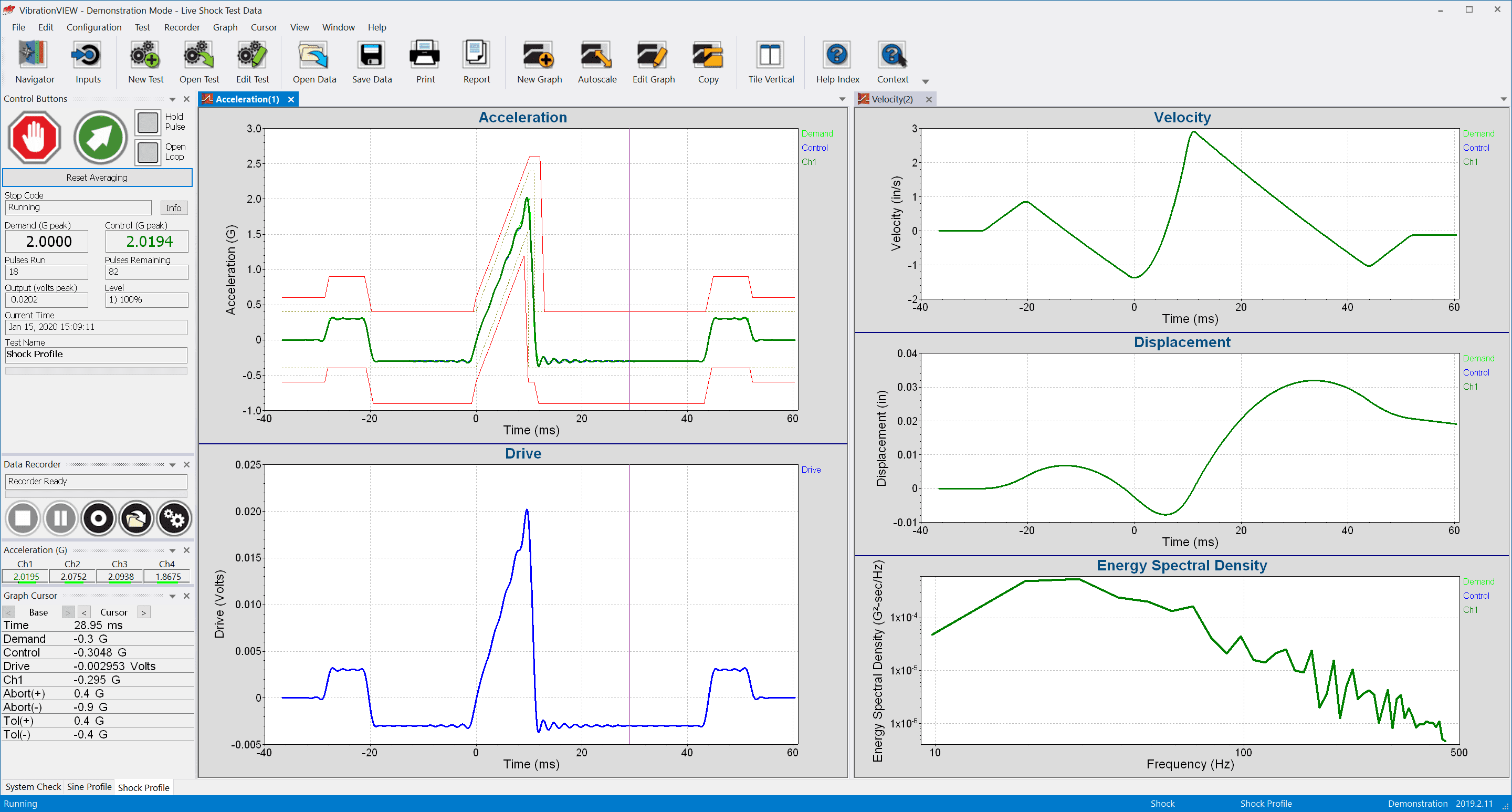

Shock

Run standard classical shock, user-defined, or SRS-synthesized transient pulses.

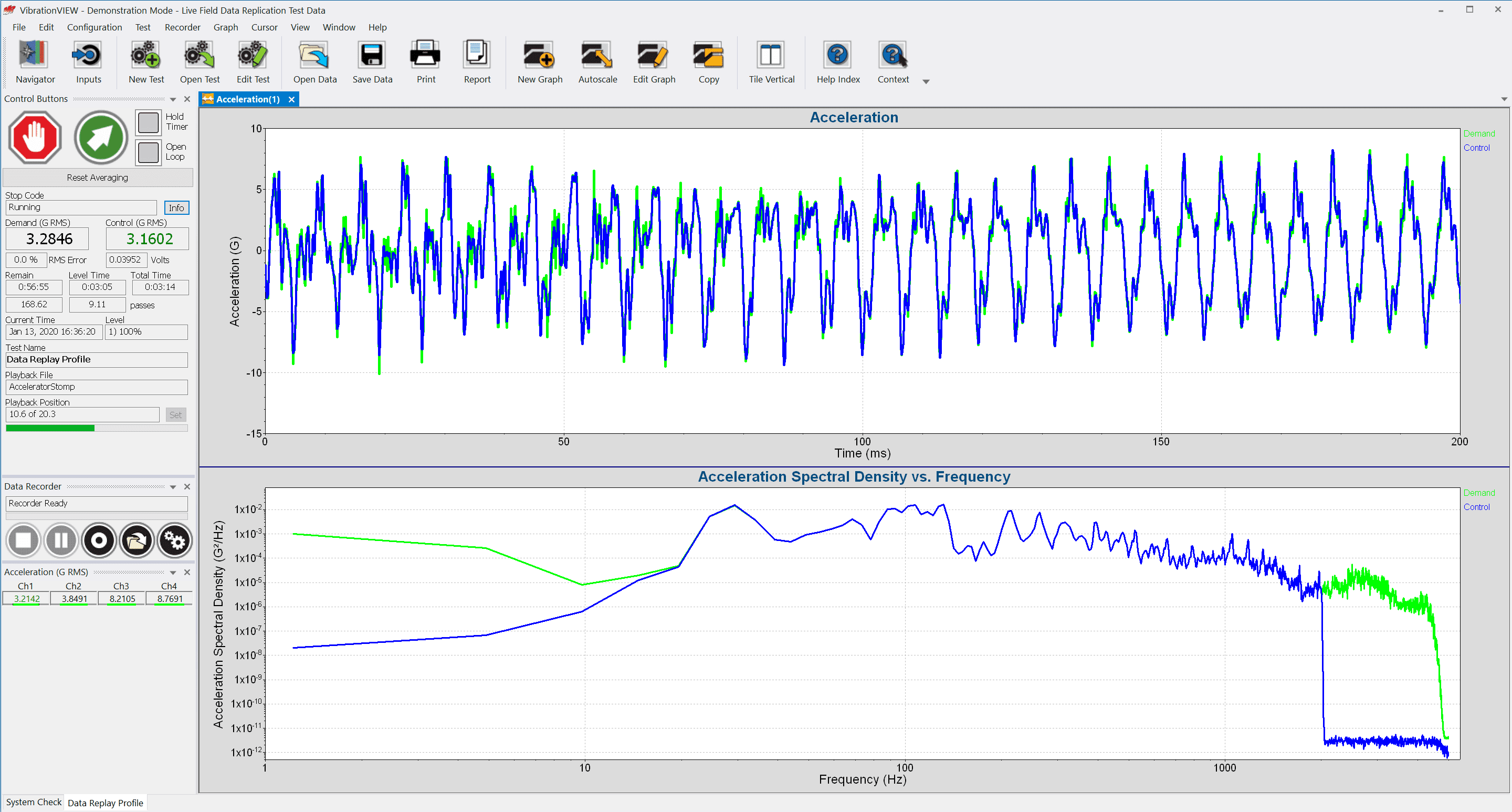

Field Data Replication

Reproduce field-recorded acceleration waveforms on a shaker in your test laboratory.

Training Programs

2-day training seminars covering general vibration principles and software (free with system purchase)

Innovation Timeline

We Develop. You Advance.

1995

FDR

Field Data Replication

Reproduce field data

on a shaker.

2005

Kurtosion®

Kurtosion

Add high peaks back

into random tests.

2010

FDS

Fatigue Damage Spectrum

Accelerate tests with

field-damage equivalency.

2015

iDOF®

Instant Degrees of Freedom

Run statistically

valid short-duration

random tests.

2020

STAG

Sine Tracking, Analysis

and Generation

Generate accelerated

SoR tests.

2023

TruClip

TruClip

Reduce high peaks on shakers the right way.

Dare to Compare

Are you skeptical about VR meeting your standards? Is your current controller out for calibration, not working, or unable to perform a test? Put us to the test.

Whether it is a brand-new system or a replacement controller, we will let you try our fully-enabled hardware and software for 30 days. Once you use it, we think you will be hooked.

Custom Reporting

With custom reports, you can define the included parameters to adhere to test standards or customer requests. Add other details such as data vectors, graphs, screen images, test notes, and company branding.

Rental Options

The VR hardware and software packages can be configured for as many or as few test modules as you would like (à la carte). You may add more at any time in the future.

In fact, our software modules are activated by electronic keys, so you can “rent” modules if you have short-term needs for specific tests. VR will apply up to 2 months of any software rental to the final purchase price.

Shaker Compatibilities

VR hardware works with any electrodynamic, servo-hydraulic, or servo-electric shaker and includes single-axis, dual-axis, dual-phase, rotational, three-axis, multi-loop/four-post, and seismic control options.

Copy & Paste

The copy and paste command in VibrationVIEW allows the user to move data between graphs and software applications. In doing so, the user can perform an easy comparison of data from a multitude of applications. This can be useful for comparing graph data from different time locations, importing test profiles, multiple test results, various test environments, and much more.

LED Rings

A channel LED is located around each of the input channel BNC connectors on the front panel of the VR9500 and VR10500. The channel LEDs provide the connection status of the integrated electronics piezo electric (IEPE) accelerometers. This is helpful in determining power, channel identity, faults, input bias voltage being marginal, or many other visual indications.

Software Modules

Full Software List

Sine

Random

Shock

Test Acceleration

Shock Response Spectrum (SRS)

Sine Resonance Track & Dwell (SRTD)

Fatigue Damage Spectrum

Report Builder

Sine-on-Random

Random-on-Random

Sine-on-Sine

Mixed Mode

TruClip

Instant Degrees of Freedom (iDOF)

Kurtosion

User Defined Transient

RecorderVIEW

Analyzer

Transient Capture

Earthquake

Field Data Replication (FDR)

Sine Reduction

Accelerometer Calibration Software

3-axis Control

Dual-loop Phase Control

Four-post Control

Multi-loop

Small Satellite

Remote Options

Web Server

DashboardVIEW

ActiveX

Math Traces & Calculator

Calibration Options

DC Offset

Random Import

Chatter Monitor

High Frequency

Automotive Vibration Testing

Aerospace Vibration Testing

Consumer Goods

Electronics Vibration Testing

Medical Vibration Testing

Military & Defense Vibration Testing

Packaging Vibration Testing

Seismic Vibration Testing

Testing Labs

University Testing Labs

View All Software Modules