When preparing to run a vibration test, a test engineer must determine which test method to run given the test goals and specifications. One option is a sine vibration test. Sine vibration is a basic wave, but how is it applied during a vibration test, and what does it accomplish? Let’s discuss:

What is Sine Testing?

A sine vibration test exposes a device under test (DUT) to a single frequency sine tone at a defined amplitude and for a set time. There are several different ways to conduct a sine test. An engineer may run a sine sweep to expose the DUT to a single sine tone with a frequency that varies across a specified range.

Following the sine sweep, the engineer can determine the DUT’s resonant frequencies. They can then expose the DUT to the resonant frequencies until a failure occurs or until a sufficient amount of time is spent at each resonance to ensure a failure will not occur in the real world.

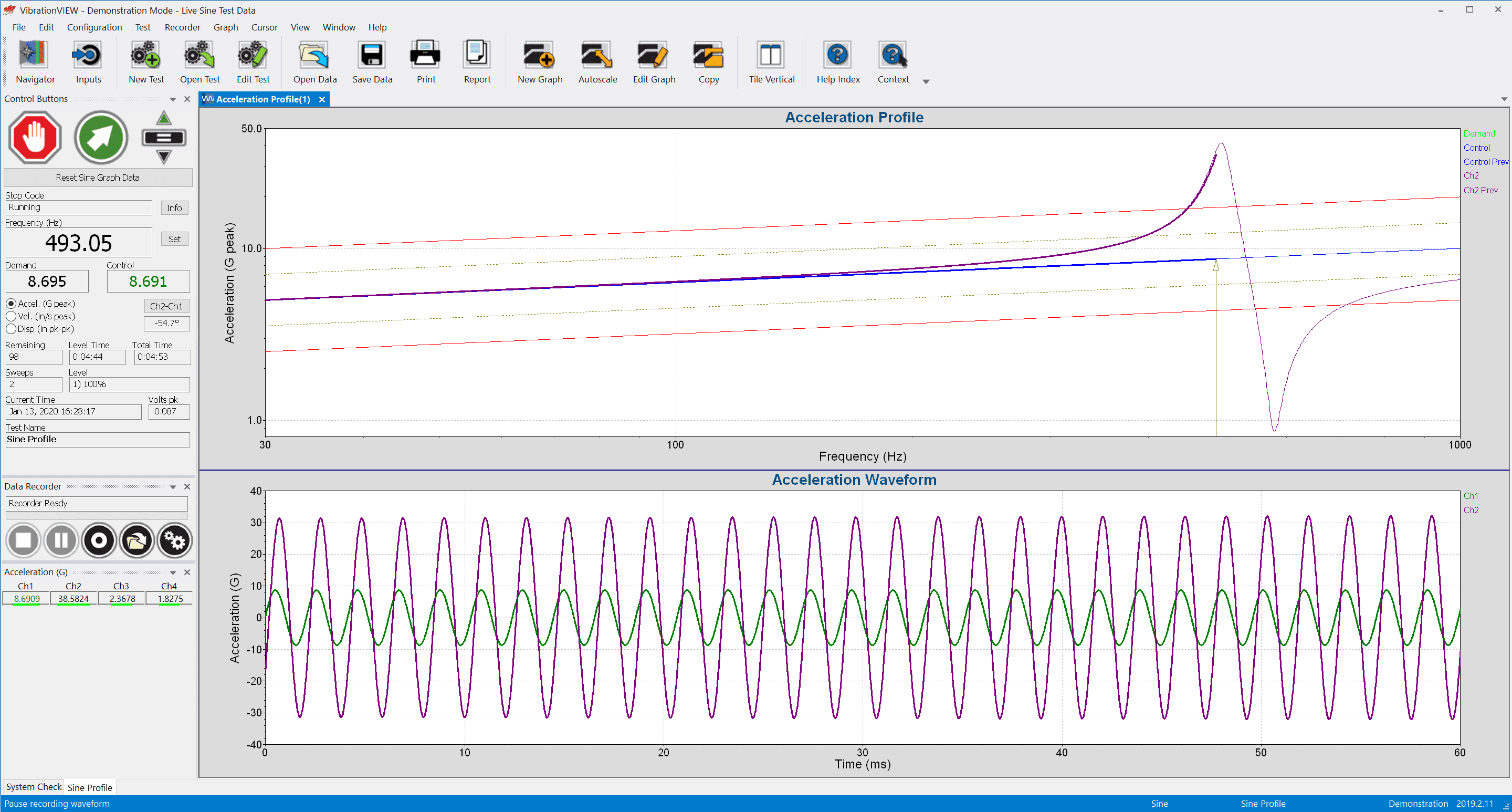

Figure 1. A sine sweep profile in VibrationVIEW.

Sine Sweep Test

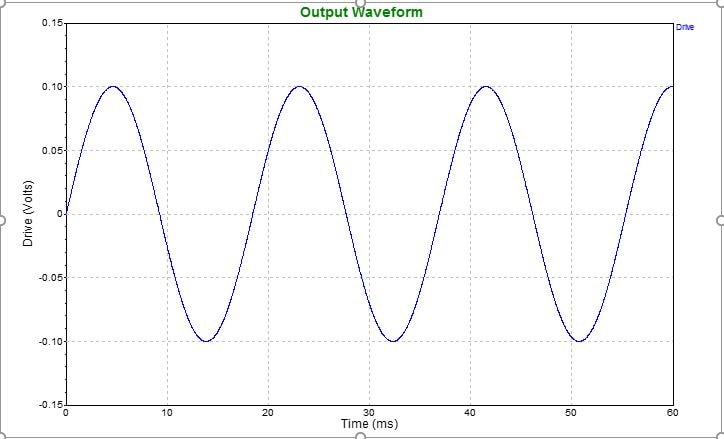

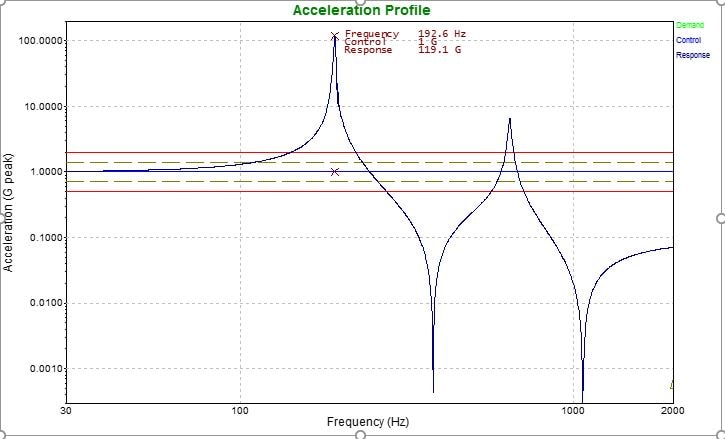

In Figure 2, the drive waveform displays a single sine tone applied to a DUT during a sine sweep test. The acceleration profile in Figure 3 shows the peak amplitudes at two points on the DUT versus frequency. The control point is the mounting point of the DUT, and the response point is the second point on the DUT.

The resonances at the response point are easily identifiable, which is the primary purpose of a sine test. The amplification factor of a resonance is typically what causes a DUT to fail. An engineer could also design the sine test to dwell at the first large resonance (192.6 Hz) until a failure occurs in the DUT or until sufficient time is spent at the resonance to ensure the DUT will not fail.

The signal driving the shaker is a clean sine tone as shown in Figure 2. The measured signal at the DUT is not always as clean. The measured signal includes harmonics and other mechanical and electrical noise sources. Sine testing requires energy to be measured and controlled at a single frequency. A tracking filter is also required to remove energy that is not at a single frequency from the measurement.

Why Should I Use a Sine Test?

Sine vibration testing is beneficial for several reasons:

- A sine test is one of the simplest tests to set up and perform.

- Sine testing is among the best ways to identify resonances in a DUT accurately.

- If a DUT has a specific resonance and the test engineer needs to know the time it takes to bring the DUT to failure (assuming the failure arises from excitation of the known resonance), a sine test at that specific frequency is an effective means to bring the DUT to failure.

- A sine test focuses all of the shaker’s power on the resonant frequency where the failure will occur.

When Should I Use Sine?

Vibration test engineers should use sine vibration testing to:

- Identify resonances in a DUT. Use a sine sweep test across a range of frequencies to identify the frequencies with the largest response signals.

- Validate Shakers. Sine tests can be used to identify any trouble with the shaker system (cracked armature, loose bolts, etc.). Periodically run a sine sweep for the shaker system to confirm that the response is the same. Variations in response, especially resonances that shift significantly, indicate issues in the shaker system.

- Validate Fixtures. Sine tests can identify resonances in fixtures. If the fixture has resonances in the test frequency range, the results of the test will be questionable.

- Qualify a product. Controllers that use a sine-track-and-dwell algorithm to adjust the sine test frequency to keep the shaker on the resonance where the DUT begins to weaken and fail can effectively fatigue a DUT to failure or demonstrate the DUT can withstand such a vibration.