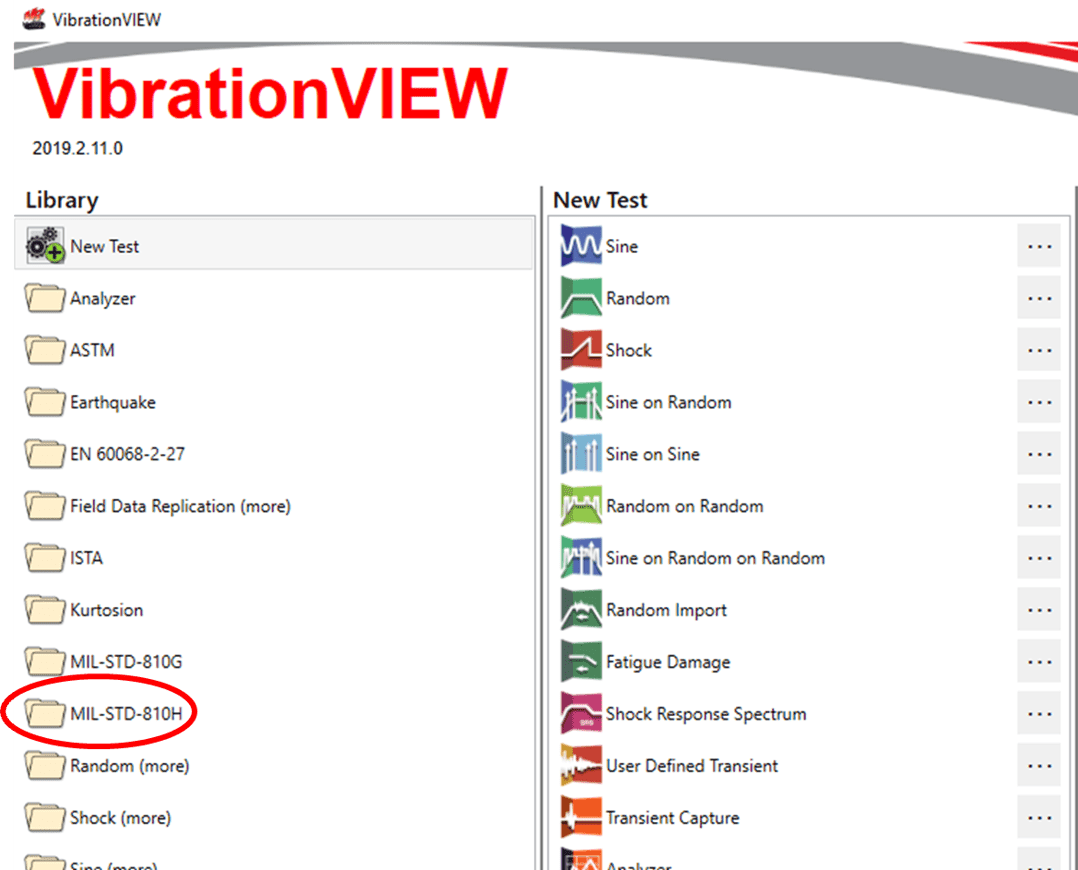

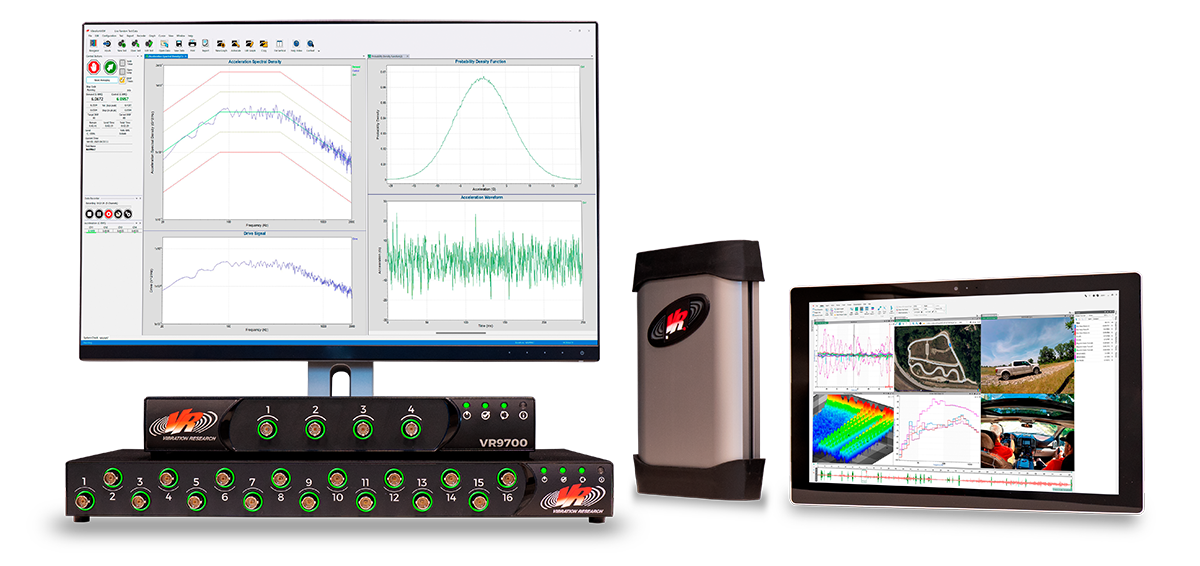

VibrationVIEW Software Package

Sine

Random

Shock

Instant Degrees of Freedom (iDOF)

Sine-on-Random

Sine-on-Sine

Shock Response Spectrum (SRS)

Transient Capture

User Defined Transient

Fulfill Test Specifications

Generate test profiles or enter specifications with ease. The VibrationVIEW interface is intuitive and user-friendly, and the software is industry-leading. Access standard vibration testing modes built for ease of use and advanced features you won’t find anywhere else.

Defense Test Specifications

Military Standards

Military and defense equipment must be able to withstand some of the harshest environments. MIL-STD Version H emphasizes a tailored approach for environmental testing and is focused on ensuring that systems withstand the extreme climatic, shock, and vibration environments expected during a service lifetime.

Vibration Research’s testing systems address acceleration, shock and transport shock, gunfire vibration, and random vibration. We’ve spent a significant amount of time with MIL-STD-810H and put the new test profiles into the current version of the VibrationVIEW software.

Military & Defense Companies Using VR Products

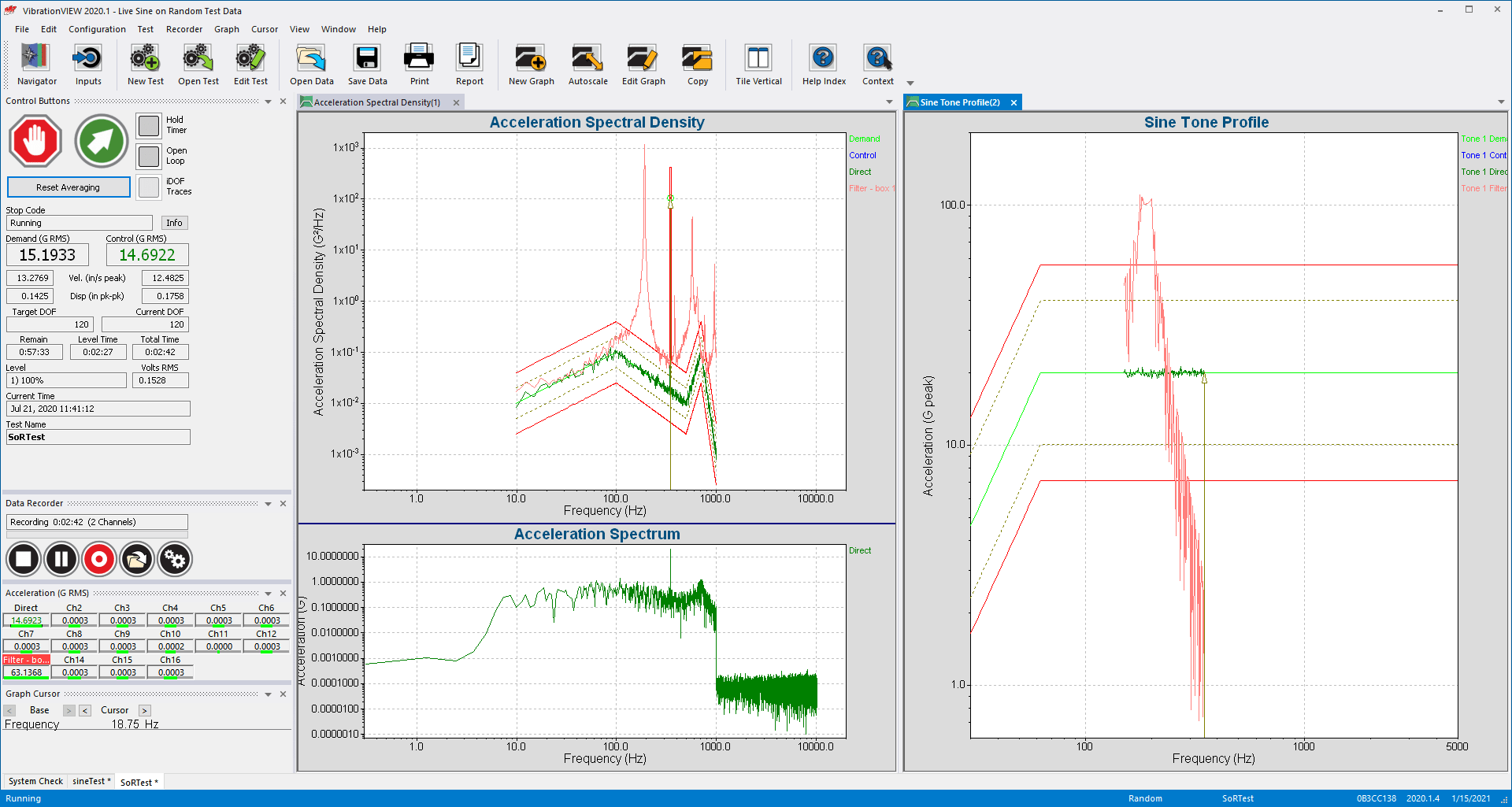

Mixed-Mode Vibration Testing

Military and defense applications typically use sine-on-random (SoR) and sine-on-sine mixed-mode vibration. Mixed-mode testing simulates complex field environments that are not purely random or sinusoidal but rather a combination of vibration modes.

A helicopter gunfire test is a common application of SoR testing. Helicopters are subject to common random vibration, but gunfire from the helicopter introduces high-G sinusoidal vibration. As an SoR test better represents real-world conditions, it is the preferred test procedure for this application.

Random Software Innovations

Instant Degrees of Freedom (iDOF)

Instant Degrees of Freedom (iDOF)

Instant Degrees of Freedom (iDOF) employs an advanced algorithm to deliver accurate and low-variance PSD estimates that are calculated quicker than traditional averaging.

With iDOF, you can verify that the control PSD is within tolerance, determine how the test affects the DUT, and stop the test before the energy from a vibration resonance inflicts damage.

Kurtosion®

Kurtosion allows you to adjust the RMS and kurtosis levels of a random test while maintaining the test profile and spectrum attributes.

TruClip™

TruClip™

Clip What Matters

TruClip predicts the drive signal and removes peaks that would exceed the acceleration, velocity, or displacement limitations of the shaker.

Define & Run Shock Tests

High Channel Count Systems

VR10500 Vibration Controller

The VR10500 is a high-powered option for advanced vibration testing. VR engineered the VR10500 to coordinate with high-channel-count and multi-shaker systems.

Features

Multi-axis with Phase Control

Test oversized products by synchronizing two shakers with the same test profile. The VR10500 vibration controller can perform dual-loop control in the Sine, Random, Shock, and FDR test modes.

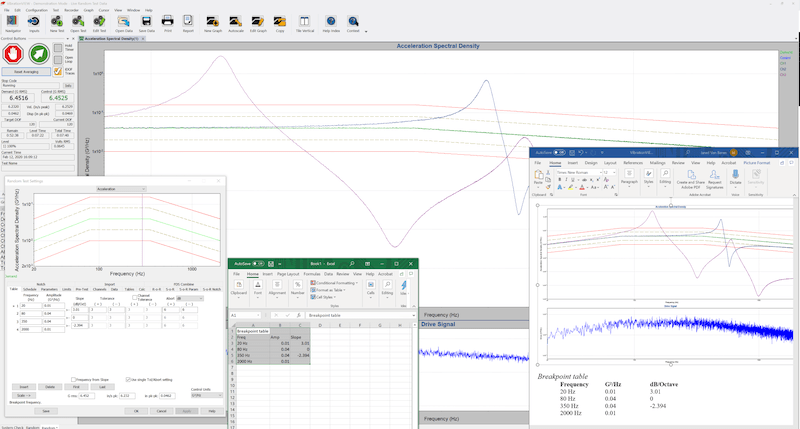

Copy > Paste in Excel & Word

Copy and paste vibration test profiles and graphs between VibrationVIEW and Microsoft Word/Excel. This feature is especially useful when sharing profiles with colleagues, entering data from a customer, or entering lengthy or complicated test profiles.

Data Acquisition & Analysis Applications Summary

- Event Triggering

- Transient Capture

- Flight Recording

- Whole Vehicle Vibration

- GPS

- In-Vehicle Data Acquisition

- Submarine Components

- Helicopter and Jet Vibration

- Video/Data Synchronization

- Order Tracking & Analysis

- PSD Analysis

- FFT Analysis

- And more!

Vibration Control Applications Summary

- Submarine Components

- Helicopter and Jet Vibration

- Random Shake Testing

- Drop Shock Testing

- Classical Shock Testing

- Swept-Sine Testing

- Pyrotechnic SRS Testing

- Flight Simulation Testing

- Launch Simulation Testing

- Component Durability & Fatigue

- Dual Axis

- Vehicle Dynamic Strain

- And more!