Control DC Offset of an Input Channel

DC Offset Control allows the COLA output on the VR9500/VR10500 to function as a secondary control loop. In doing so, the user can control the DC offset of a selected input channel.

The user can specify which channel to use for closed-loop control. The input must be configured as a DC input and have the same unit category as the DC signal.

COLA Output

The COLA output provides a voltage sync signal to external equipment. Aside from DC Offset Control, the COLA output can be differential, sine, or square, or can function as a DC frequency reference, a phase-controlled second output for multi-axis testing, or control only.

VR Controller Hardware

VR9500 I/O Unit

Vibration Research’s best-selling control hardware for vibration and shock testing. Scalable to 128 channels and compatible with all electrodynamic and servo-hydraulic shakers. Features include up to 200kHz sample rate and 2 outputs.

VR10500 I/O Unit

Vibration Research’s high channel count control hardware for vibration and shock testing. Scalable to 512 channels and compatible with all electrodynamic and servo-hydraulic shakers. Features include up to 256kHz sample rate and 4 outputs for multiple shakers.

DC Offset Parameters

The DC Offset parameters control the functionality of DC Offset Control. The user can define the scaling factor for the DC output using the units and Volts parameters. The parameters also control the DC Offset Reference option.

DC Offset Reference

The DC Offset parameters also control the DC Offset Reference option. DC Offset Reference uses the COLA to output an open loop DC voltage proportional to a user-configured engineering unit. The desired output level is configured on a per schedule level basis within the test settings.

DC Offset Control for Amature Centering

Control Motor Operation

With the optional Motor Control add-on, the user can schedule motor operation in the Sine software. For example, an engineer can control a shaker and drive the test item’s motor simultaneously.

The VibrationVIEW software performs motor control by using the COLA as a DC Offset Reference or DC Offset Control. The controller outputs a DC signal proportional to the user-specified value.

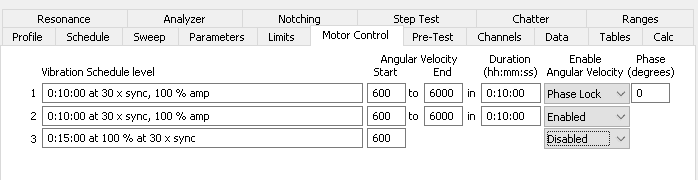

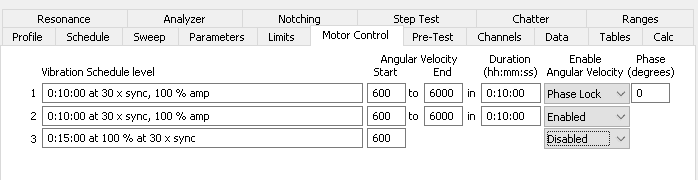

In the Motor Control settings, the user enables, disables, or phase locks the angular velocity and sets the phase value.

- Enabling the angular velocity brings the motor to the user-specified level

- Phase Lock enables the output and locks the phase between the drive signal and the external motor to the user-specified phase value

- The Disable option disables the motor and prevents the COLA from sending a DC signal

The user can also use the motor control settings to configure a sine sweep by defining start and end levels and a sweep rate.