Shock Testing Software

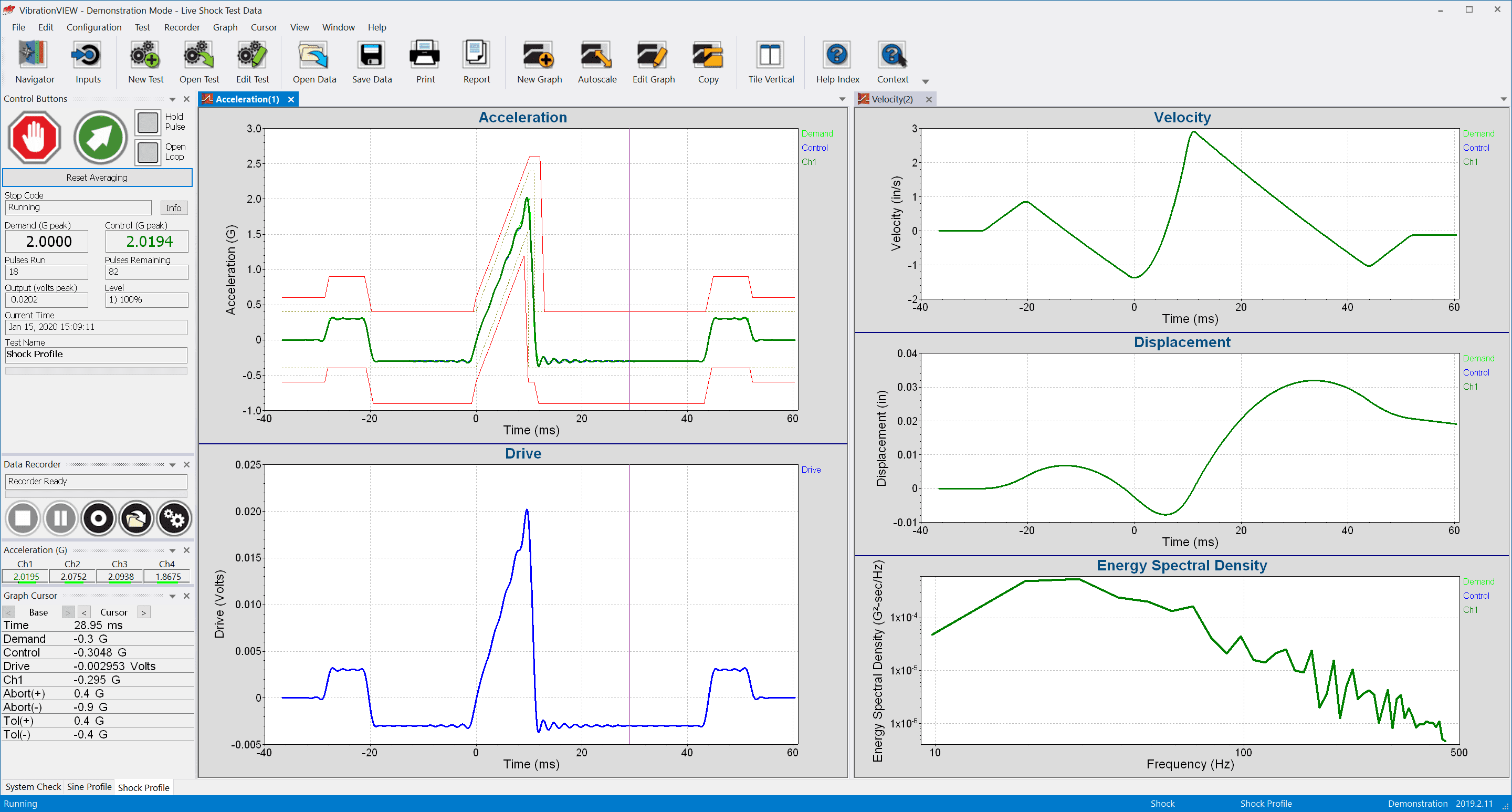

Perform drop shock testing with the intuitive Shock software. It includes the standard classical shock pulses and the option to vary pre/post-pulse compensation amplitude and shape. Select the user-defined transient option to build a pulse from a recorded waveform.

-

- Enter up to 200 separate levels and loop to repeat sequences

- Select pre-defined tolerances from common test standards

- Use the shock response spectrum (SRS) for complex pulses

Record Transient Events

In the Laboratory

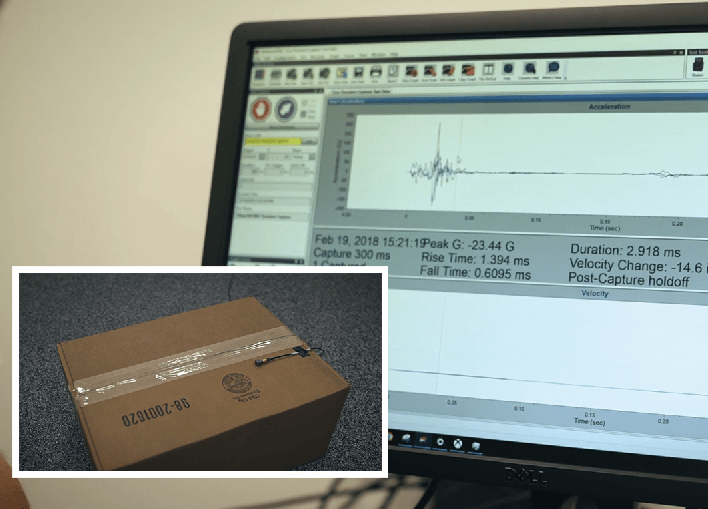

Record a transient waveform during a shock test to use post-process with the Transient Capture software.

Record a transient waveform during a shock test to use post-process with the Transient Capture software.

Define the triggering and data capture settings pre-test and allow the VibrationVIEW software to handle the rest. Use the captured waveform(s) alongside the acquired data or for analysis with the shock response spectrum (SRS).

Transient Capture Software Features

-

- Record 524,032 (64-bit version) or 65,280 (32-bit version) samples

- Set a hold-off period to ignore triggers after the captured event

- Apply digital filters to the input waveforms

- Enable MIL-STD constraints on the pulse

- Set tolerances outside the range of the pulse definition

In the Field

Record transient events that occur in the field environment with the portable ObserVR1000 data acquisition hardware. Bring the recordings back to the lab for analysis or test development.

Electric Vehicle Battery Drop Shock Test

Drop shock testing is standard in the packaging industry but is applicable to many. Electric vehicle batteries (and other lithium-ion batteries) must meet international standards before shipment.

Drop Shock Test Standards

VibrationVIEW includes pre-defined test profiles to meet common shock test standards. Save a new test profile for quick repeatability.

- IEC 60068-2-27, IEC 60068-2-29, and IEC 60068-2-31

- ISTA 6-Amazon-Over Box and ISTA 6-Amazon-SIOC

- SAE J1455

- MIL-STD-810

- DO-106

- EN 60068-2-27

Test Types

-

- Freefall

- Rotational edge drop

- Incline/horizontal impact

- Pyro-shock

- and more

Data Analysis

Import field recordings into the ObserVIEW software for post-process analysis, including waveform editing, resampling, filtering, and custom math operations.

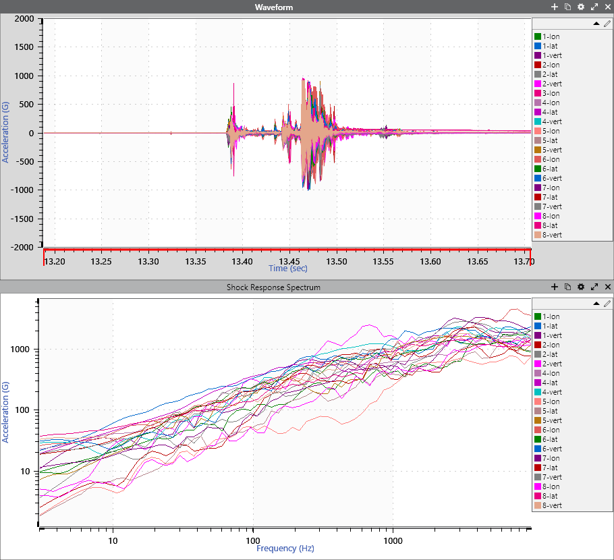

Shock Response Spectrum

Engineers can generate a shock response spectrum from a shock recording to analyze complex transient events.

Use the software to create an SRS test equivalent to the operational environment or validate an SRS test profile before running it on a shaker.

Learn how to generate an enveloped SRS curve in ObserVIEW for vibration control. Quick tip video.

What is the difference between a drop shock machine and an electrodynamic shaker?

A drop shock machine can arrest movement using a mechanical method. A shaker cannot, so pre-/post- pulse compensation must be used instead. Moreover, a drop shock machine is capable of large changes in velocity and displacement.

While most classical shock pulses are defined in units of acceleration, the purpose of a shock test is to generate a delta-velocity and then determine its effect on the product. Drop tests were designed to generate a unipolar acceleration shape and a set delta-velocity.

When do I need to add pre-/post-pulse compensation?

Shakers can only generate a fixed amount of velocity and displacement, and continuous velocity and displacement can be dangerous and lead to damage. Therefore, pre-/post- compensation pulses must be added to stop the generated signal.

Compared to a mechanical shock machine, a shaker can be a reliable and efficient option for routine shock testing. To run a classical shock test on a shaker, however, the pulse must start and end at zero acceleration, velocity, and displacement. Pre-/post- compensation pulses are used to drive the shaker to these zero parameters.