Sine resonance track and dwell (SRTD) appears to be a straightforward vibration test. You run a sine sweep, identify a resonant frequency, then dwell on the resonance for a pre-determined time or until the device fails.

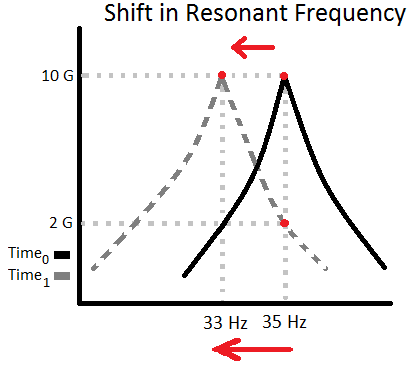

However, resonances shift as material fatigues, and the test frequency should shift correspondingly. The test engineer needs insight into the resonance shift(s). Ideally, they should gather details on multiple resonances and select a resonance for a sine dwell to run the test confidently.

Confidence in the SRTD frequency shift is critical, but it is difficult to achieve without the right tools. Fortunately, the Sine Resonance Track and Dwell software is an easy and budget-friendly option with this capability, especially for labs already using VibrationVIEW for Sine.

With the SRTD vibration testing software, you can run a sweep, then display a resonance table with details. The software automatically selects resonances; it uses the transmissibility between input and response as the determining characteristic of a resonance. For each identified frequency, the software displays the transmissibility, phase relationship, and Q-factor.

Phase Tracking

The most common way to shift resonance frequencies is phase tracking, which is implemented by the vibration test controller software.

At the end of a sine sweep, the software measures the phase difference between the control and response channel at the resonance frequency. In the real world, the phase difference is usually close to (but not exactly) 90°. As the material fatigues and the resonant frequency shifts, the software tracks the shift by adjusting the drive output to maintain a constant phase relationship between the two channels.

![]()

Engineers can watch the shifts in real-time while capturing information for graphing and reporting. Most importantly, they can be confident their dwell is performing a valid test.

This approach is better than no adjustments but has limitations. Mostly, the phase difference at peak transmissibility will often change as the effects of fatigue progress.

Peak Tracking

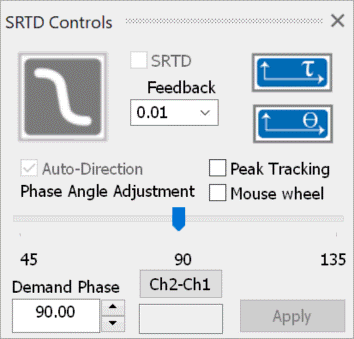

SRTD controls in VibrationVIEW.

Peak tracking is a technique that finds and maintains the peak transmissibility between two channels. It constantly oscillates the phase between the two channels and observes if the peak transmissibility increases or decreases. As more data are collected, the phase change becomes narrower in frequency and slower in time. This action limits the oscillation while accurately tracking the peak.

This powerful feature minimizes the need for precise detection during a sine sweep so the test can sweep faster. Most importantly, it ensures that peak transmissibility is maintained throughout the tracked dwell portion of the test.

Experimental Comparison

Theoretically, peak tracking should outperform phase tracking. However, test engineers generally prefer data to theory. In that spirit, VR ran a series of SRTD tests and compared the two tracking methods.

Fifty tests were conducted on notched aluminum beams: twenty-five using peak tracking and twenty-five using phase tracking. One end of the aluminum beam was attached to a shaker head, and a mass hung from the cantilevered end of the beam.

Peak tracking caused the aluminum beams to fail faster than phase tracking. Review the paper “Experimental Comparison of SRTD Tracking Methods” for a complete description of the resonance tracking methods and detailed test results.

A Quick, Cost-effective Upgrade

Customers with VibrationVIEW’s Sine software can add the SRTD vibration testing software with an electronic key. To learn more, visit the software page.