Abstract

This technical note answers frequently asked questions about the fatigue damage spectrum (FDS).

What is the Purpose of FDS?

The fatigue damage spectrum (FDS) in ObserVIEW is a fatigue analysis and test generation tool. Engineers can use it to create a random test profile that is the damage equivalent to multiple time-history waveform files from the operational environment. They can use the profile for comparison or export it for vibration testing on a shaker in a lab.

Engineers can also use ObserVIEW’s FDS analysis options to compare product failure runs, compare specifications to real-world data, and determine if their current testing method is valid, over-testing, or under-testing.

Is it Possible to Combine Multiple Time-history Files?

ObserVIEW’s FDS software can generate a power spectral density (PSD) test profile from multiple time-history files. These time-history files can be weighted individually by time or cycles to achieve an accurate target life for the product. When combining the data, the software uses the same m, Q, and frequency range to create an equal relationship between the imported files. The output PSD will be the damage equivalent of the imported files based on the target life for each waveform and the FDS settings.

For instructions on creating an FDS test profile, see the tech note Create an FDS-Generated Random Test in ObserVIEW.

Does the FDS Include Resonances?

Properly recorded field data includes resonances. If the recorded file has resonances, the FDS will include them in the test profile.

To What Degree Can a Test be Accelerated? Is There a Recommended Ratio?

An accelerated test is not equivalent to running the test for its lifespan. Generally, the less the test is accelerated, the more accurately it reflects the real world. At a minimum, the test cannot exceed the product’s instantaneous stress limit, such as yield stress or ultimate stress (assuming the product fails due to fatigue damage). The instantaneous stress limit varies depending on product construction.

Additionally, the FDS uses the stress-strain curve to determine the acceleration, so the test acceleration is only as accurate as the m value. As the test acceleration level increases, the more important the m accuracy becomes. Some composite materials may make it difficult to estimate the m value.

According to MIL-STD-810G, test engineers should not accelerate tests by applying excessive amplitudes “simply to achieve short test durations. Such excessive amplitudes may lead to wholly unrepresentative failures and cause suppliers to design material to withstand arbitrary tests rather than the in-service conditions” (p. 237).

The military standard also defines an exaggeration factor. “It is recommended that the exaggeration factor be kept to a minimum value consistent with the constraints of in-service time and desired time, and should generally not exceed values of 1.414^(S1/S2) or 2^(W(f)1/W(f)2).” According to this statement, for material with an m value of 7.5, the maximum ratio between the in-service time and test time is 1.414^(7.5) ≈ 13.4.

ERS for Validating Test Acceleration

To help determine how much acceleration is “just right,” engineers can use the extreme response spectrum (ERS). If the accelerated test’s extreme response exceeds the ERS tolerance, then the test acceleration must be reduced. Learn more.

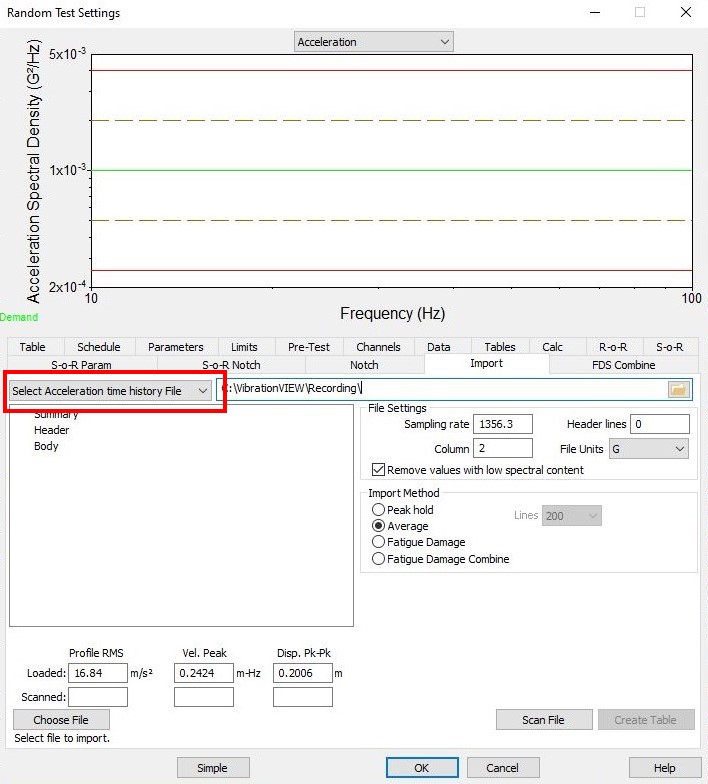

How Can I Create a Time-history File from a PSD?

In VibrationVIEW, the simplest method to produce a time-history file from a PSD is to use the Random Import function. Import the PSD, run the test, and record the Ch1 time waveform. You can use demonstration mode or loop the drive to Ch1 with a short BNC cable. Connection to a shaker is unnecessary because a PSD is not unique to any time waveform. The FDS is a time-based algorithm; if you run the same PSD repeatedly, you will not produce the same FDS but a good approximation.

A second option is to assume random phases using a tool like MATLAB, but the results would not be significantly different.

Is it Possible to Determine How Much Damage a PSD Causes?

Not by itself. A PSD is only associated with a time waveform. The FDS also requires the product’s material properties. You can generate an FDS with a time-history file and the product’s m and Q values.

Can the FDS Determine Which PSD Causes More Damage?

To compare two PSDs using the FDS, the m and Q value must be the same. From this perspective, the FDS is an identical transformation applied to both PSDs, and the FDS generation process does not provide any new information. The comparison would provide a direct comparison of the PSDs in the frequency domain.

An example of a useful FDS comparison uses field time-history data and a PSD based on a test specification. The two FDS should align closely if the standard PSD accurately reflects the combination of field environments. This comparison can validate a PSD and assure the engineer that a product is not being over-tested or under-tested.

What m and Q Values should I Use? Is it Possible to Determine a Product’s m and Q?

See the m and Q Values for FDS technical note for information.

How Does Kurtosis Factor Into PSD Import?

Measuring the acceleration waveform in the field includes the measurement of kurtosis. When we calculate the FDS, an increased kurtosis will result in more damage at nearly all frequencies (if performed correctly). However, if we convert the FDS back into acceleration spectral density (ASD), the ASD will be Gaussian, where the kurtosis equals 3. The damage due to the time-history file’s kurtosis is calculated into the FDS but spread throughout the ASD during PSD import.

The Kurtosion® software can output an FDS with a higher kurtosis. A higher value may be useful for lowering the GRMS requirement of the test. The GRMS will be decreased, but the peak requirement will increase. Lowering the GRMS may be beneficial when a system cannot handle the sustained load of the test but can reach higher peaks.

A higher kurtosis FDS can also create peaks equal to the input waveform. With or without added kurtosis, the output PSD from the FDS will be the damage equivalent to the combined input time-history files.

Learn More

If you still have questions after browsing these fatigue damage spectrum FAQs, please reach out to the Vibration Research support team.