VibrationVIEW Software Package

Sine

Random

Shock

Fatigue Damage Spectrum

Transient Capture

Kurtosion

RecorderVIEW

Field Data Replication (FDR)

Fulfill Packaging Test Specifications

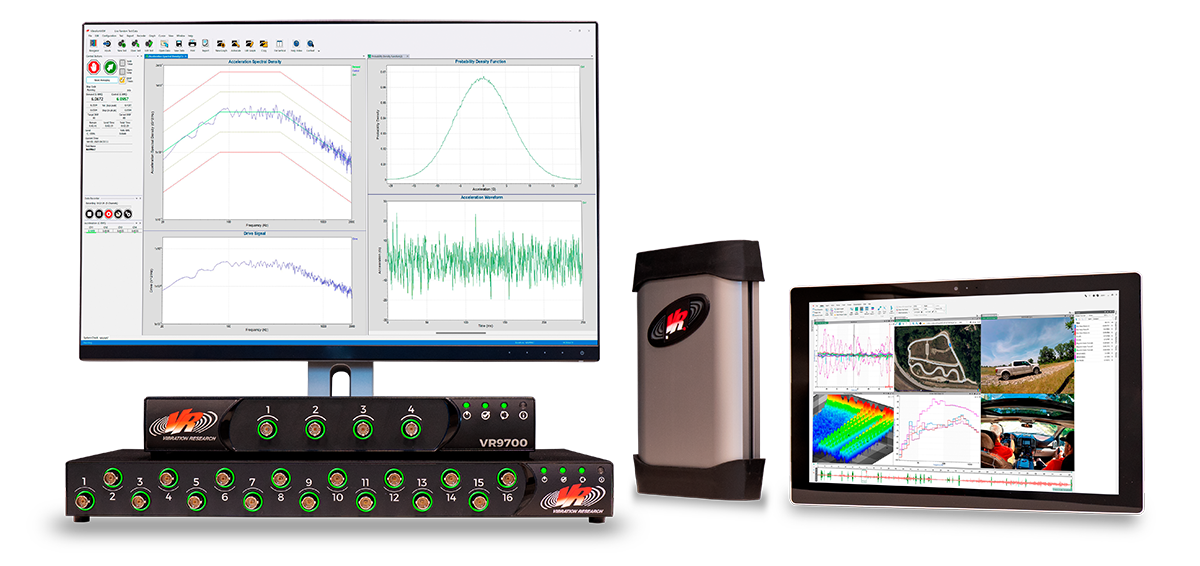

Generate test profiles or enter specifications with ease. The VibrationVIEW interface is intuitive and user-friendly, and the software is industry-leading. Access standard vibration testing modes built for ease of use and advanced features you won’t find anywhere else.

Industry Test Specifications

|

|

|

|

|

|

ISTA 6-Amazon

Amazon Packaging Support and Supplier Network (APASS) certified labs are approved to perform ISTA 6-Amazon tests and provide certification. Independent testing labs can participate in vendor certification and create new revenue streams.

- ISTA 6-Amazon-Over Box

- ISTA 6-Amazon-SIOC

Perform a Drop Shock Test

Test a packaged item’s capability to survive a drop, hit, impact, fall, or any other source of transient vibration that may occur in transit. More on drop shock testing.

Define & Run Random Tests

Validate Package Durability

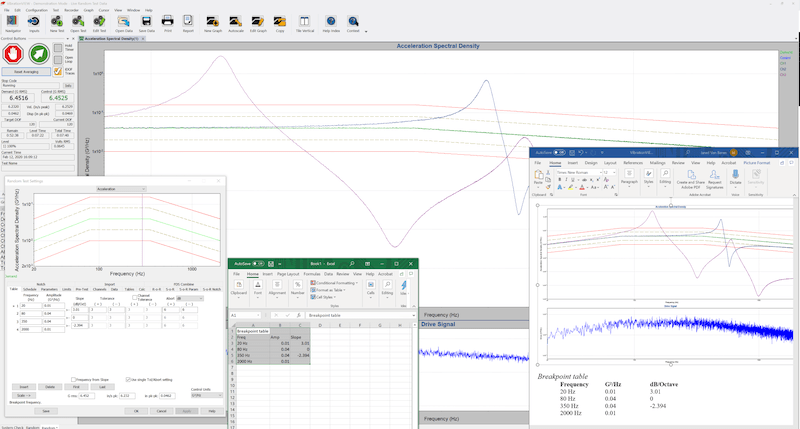

Fulfill test standards with random software features such as:

- Control any electrodynamic or servo-hydraulic shaker

- Frequency/amplitude breakpoint table (up to 9,999 entries)

- Easy-to-read tabular format

- Power spectral density (PSD) and probability density function (PDF) display

- ASTM/ISTA test profile templates

Create Profiles from Field Data

VibrationVIEW offers several test development methods to replicate the original environment of a product using recorded data. The result is a test profile that closely reflects—or is the equivalent to—the field environment.

Customizable Automated Reporting

With VibrationVIEW’s custom reporting options, you can define the included parameters to adhere to test standards or customer requests. Add other details such as data vectors, graphs, screen images, test notes, and company branding.

FedEx Package Shipping Case Study

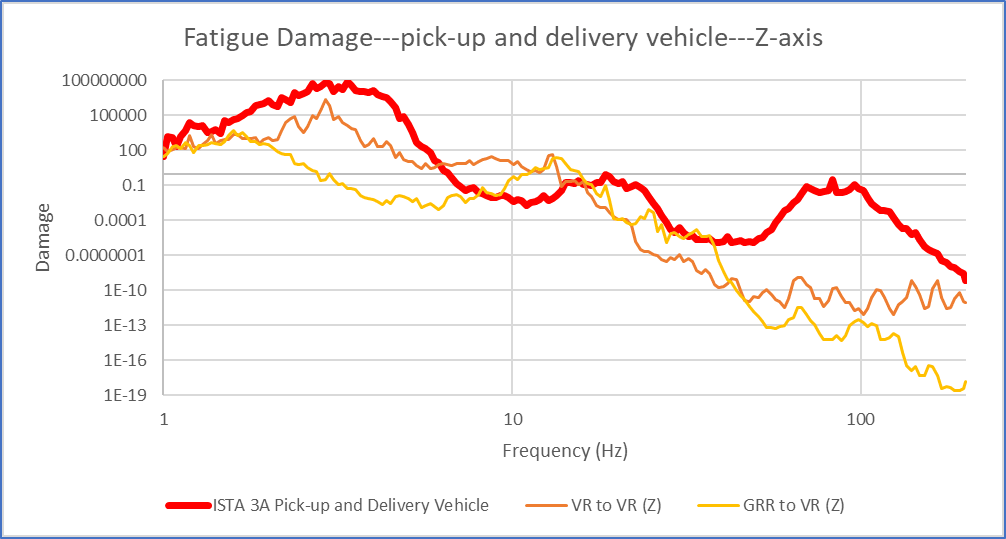

VR outlines a process for establishing a valid and meaningful comparison between real-world data and an industry-standard test specification.

Recorded time history files from a commercially shipped package were used to develop a fatigue damage spectrum (FDS). Using the FDS software, a test profile was created replicating a product lifetime of damage. Finally, the FDS and test profile were compared with similar files generated from the ISTA 3 industry standard test specification.

Copy > Paste in Excel & Word

Copy and paste vibration test profiles and graphs between VibrationVIEW and Microsoft Word/Excel. This feature is especially useful when sharing profiles with colleagues, entering data from a customer, or entering lengthy or complicated test profiles.