Systems for Low-noise Operations

The VR9500 and VR10500 controllers have a low noise floor (<70nV/sqrt{Hz}) with a 130dB dynamic range. They are compatible with all shakers and do not require a special board in the controlling PC.

VR9500

4-channel stackable unit with a range of 1 to 128 channels and two 24-bit output channels.

VR10500

16-channel stackable unit with a range of 8 to 512 channels and four 32-bit output channels for multiple shaker control.

Octave Analysis

Octave analysis allows for the objective evaluation of sound and vibration. The ObserVIEW software generates octave bands with an 8th-order filter to meet IEC 61260-1 Class 1 filter specifications.

- Fast/slow or user-defined time weightings

- Linear or exponential averaging or peak hold

- A, C, and Z frequency weighting to meet IEC 61672-1

Multi-axis Control

Multi-axis vibration testing brings products to fatigue failure faster and is more realistic than sequential, single-axis testing.

Replicate On-Road Conditions

VibrationVIEW includes several methods of test profile development that use recorded data to replicate the operation of a component. The result is a test profile that closely reflects—or is the equivalent to—the field environment.

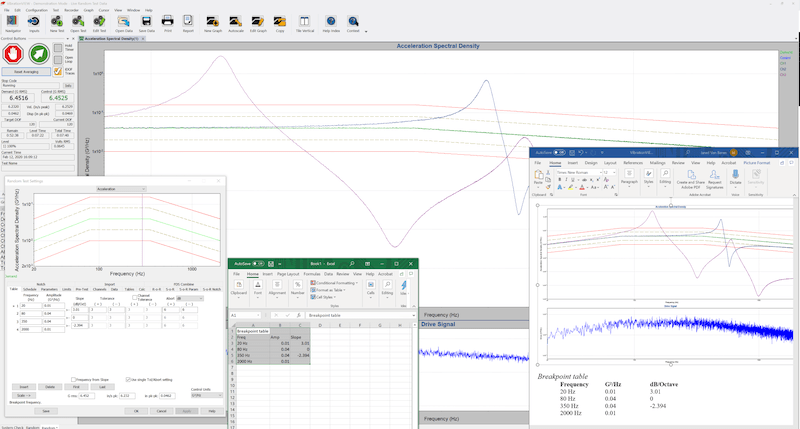

Early Detection of BSR

Ideally, an engineer will identify most issues with BSR early on by running vehicle test profiles on a shaker. The VibrationVIEW software features reliable sine, random, and shock control.

Set up and perform a test with ease and access valuable graph displays such as the power spectral density and fast Fourier transform. Download a free demo and put the software to the test.

What is BSR Testing?

BSR uses vibration to induce responses that can be detected through acoustic analysis. Engineers use these types of tests to evaluate vehicle components based on the noise they generate while in use. The test results can depend on a human interpretation of the noise or sound quality metrics such as loudness, kurtosis, and roughness.

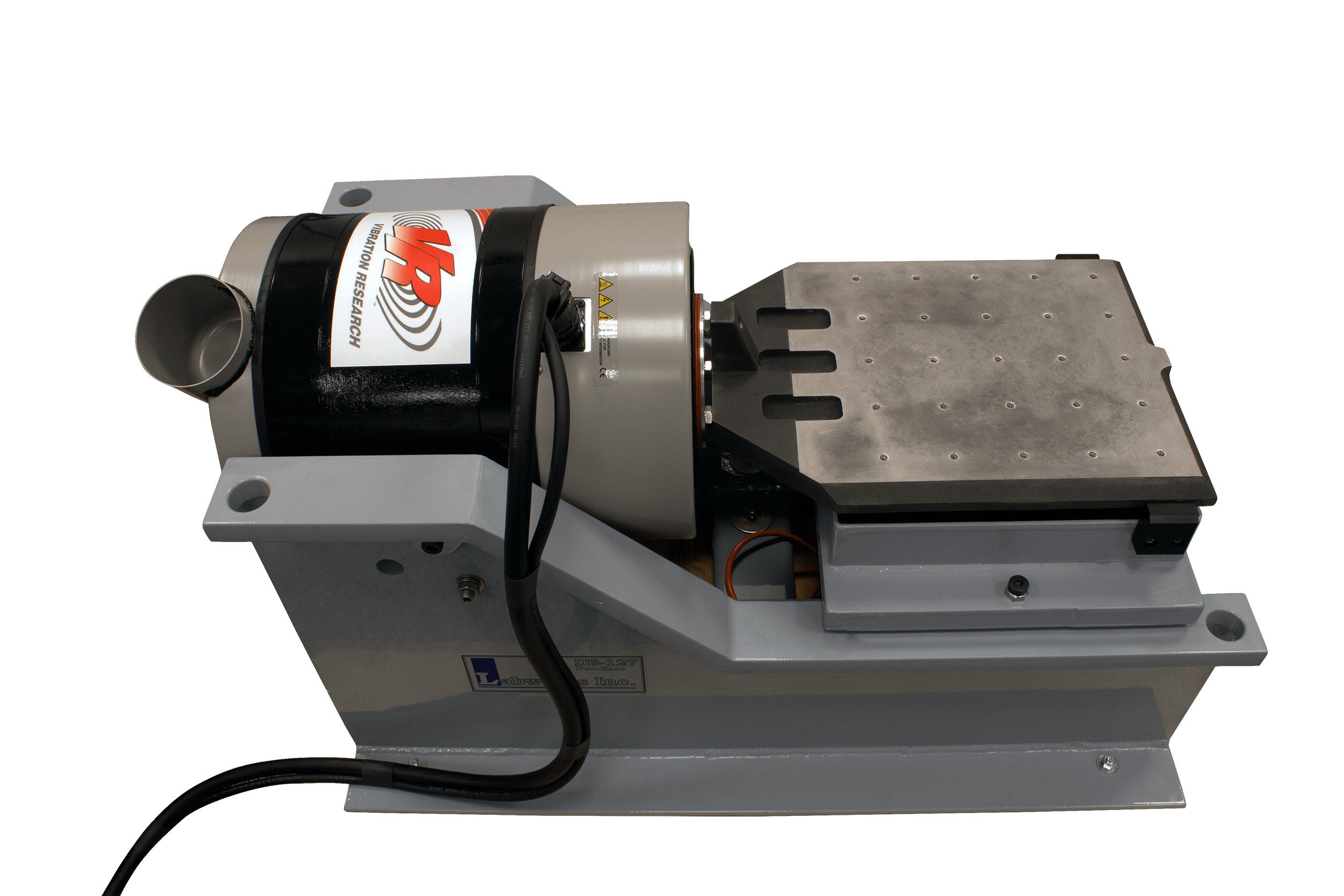

What System does BSR Require?

BSR testing calls for control hardware and shakers customized for low-noise operations such as sound limit testing, sound recordings, and anechoic chambers. BSR-approved electrodynamic shakers are customized for low noise operation.