Data Recording

In the Lab or On the Road

Control the ObserVR1000 data acquisition system remotely with the VR Mobile application, which runs on a smartphone or tablet using a WiFi connection. Set up, monitor, and modify field data recording without a wired configuration.

- Tachometer inputs

- GPS capabilities

- 6+ hour battery life

- On-board storage

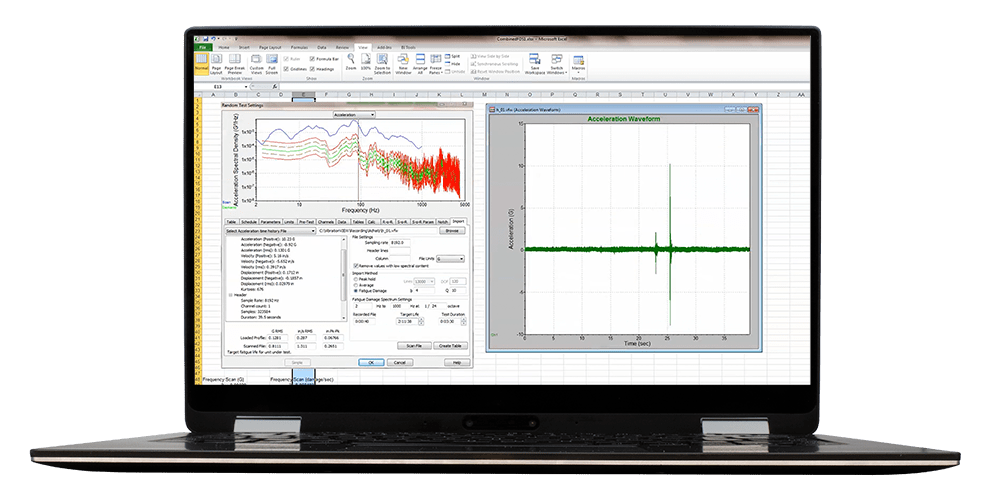

VibrationVIEW Software Package

Sine

Random

Shock

Sine Resonance Track & Dwell (SRTD)

Test Acceleration

Field Data Replication (FDR)

Fatigue Damage Spectrum

Instant Degrees of Freedom (iDOF)

Random Import

Evaluate Comfort

Build and Run a Shaker Test Profile

The bike tires and suspension system helps to dampen vibrations, but new parts add weight, and the motor introduces vibration. E-bike product development requires testing to evaluate comfort compared to recommended values.

- Generate vibration tests from recorded or historical data, including random, sine-on-random, and shock

- Measure amplitude at contact points such as the seat and handlebars in the x, y, and z directions

- Evaluate data with a weighted RMS value according to ISO 2631

- Output customized reports manually or on a schedule

- Examine the coupled effect of the power drive and road conditions with a transmissibility plot

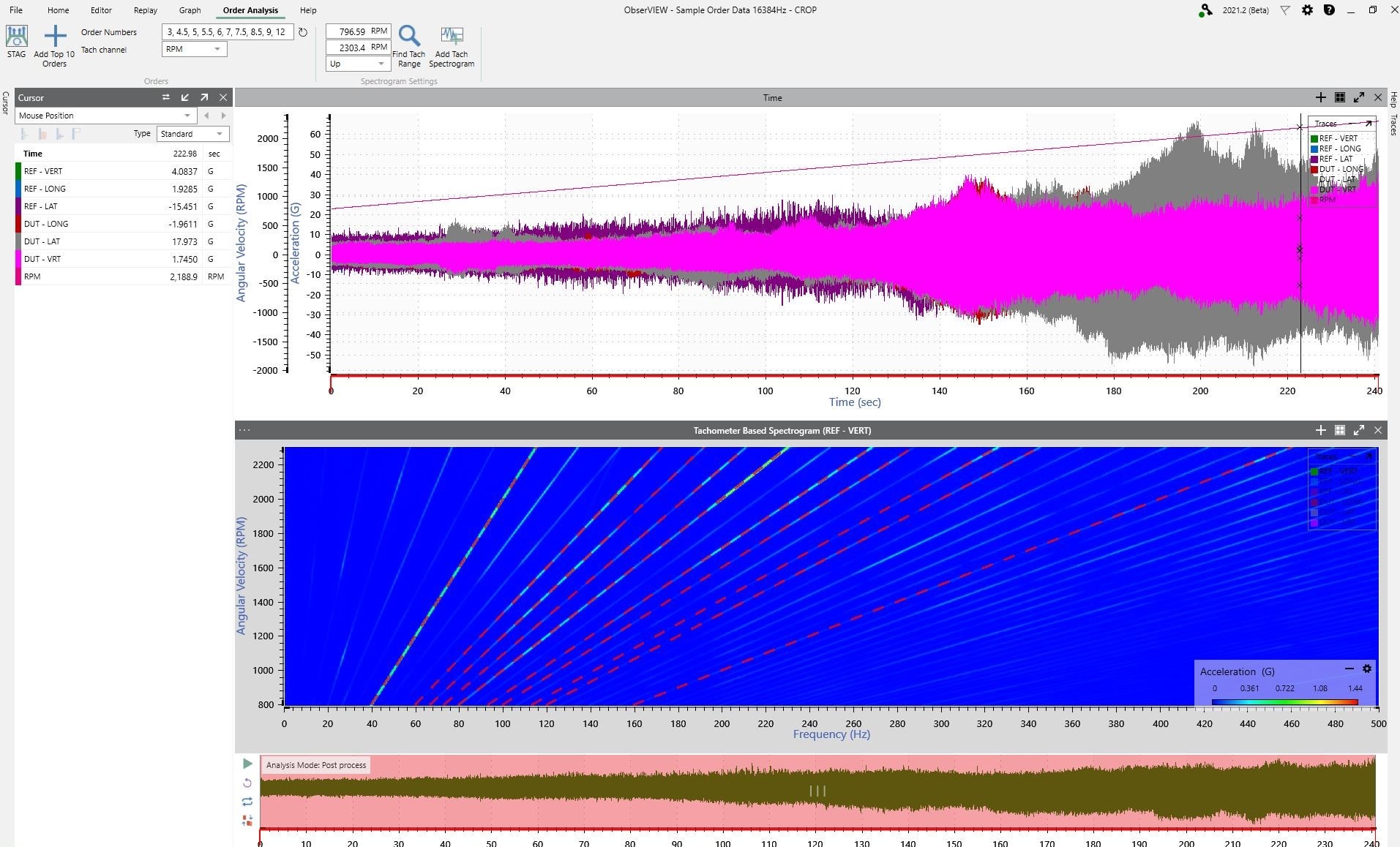

Order Tracking and Analysis

Examine Rotational Behavior

Analyze the response of the e-bike’s motor system to different RPMs and identify how the component’s vibration contributes to the overall level. Order analysis helps locate and prevent product failure relating to rotational sources of vibration.

- Analyze the noise and vibration of a motor or other rotational component

- Run a ramp up or coast down to evaluate the effects of change in speed

- Separate rotational content from the background random

- View the strength of a signal over time/angular velocity at various frequencies

- Compare data in different domains

E-Bike Analysis with ObserVIEW Math

ObserVIEW’s Math feature plots a user-defined math equation on a time or frequency-domain graph. It allows the user to implement custom math operations not defined by the current graph types.

Math channels allow for per-channel filtering, channel combining to create new channels in units of angle, or creating synthesized waveforms.

Math traces allow for templated spectrum math analysis: create an envelope or average PSDs, create trace ratios for comparison, analyze average control on recordings, or compare data to pasted tolerance lines.