Scheduled System Shutdown

Vibration tests often end after business hours. However, the shaker, amplifier, and blower continue to consume energy after the test is completed. The VR9601 Wired Remote Control option can shut down the shaker, amplifier, and blower as a scheduled function upon the completion of a test.

The Wired Remote Control option pays for itself in a short period.

| Average hours/month equipment remains on after completion of a test (less than 1 weekend) | 40 hours |

| Typical hourly energy consumption of idle equipment (including the cost of air conditioning) | 25 kW |

| Typical cost per kWh | $0.12 |

| Typical monthly energy cost of idle equipment | $120.00 |

| List price for VR9601 | $910.00 |

| Simple payback | 8 months |

Source: www.eia.gov/electricity/state/

Shaker Compatibility

Already have an energy-efficient shaker? The Vibration Research controllers are compatible with any electrodynamic or servo-hydraulic shaker. Testing labs worldwide trust Vibration Research for the industry’s best testing systems and support that delivers unrivaled value.

Source of Energy Consumption

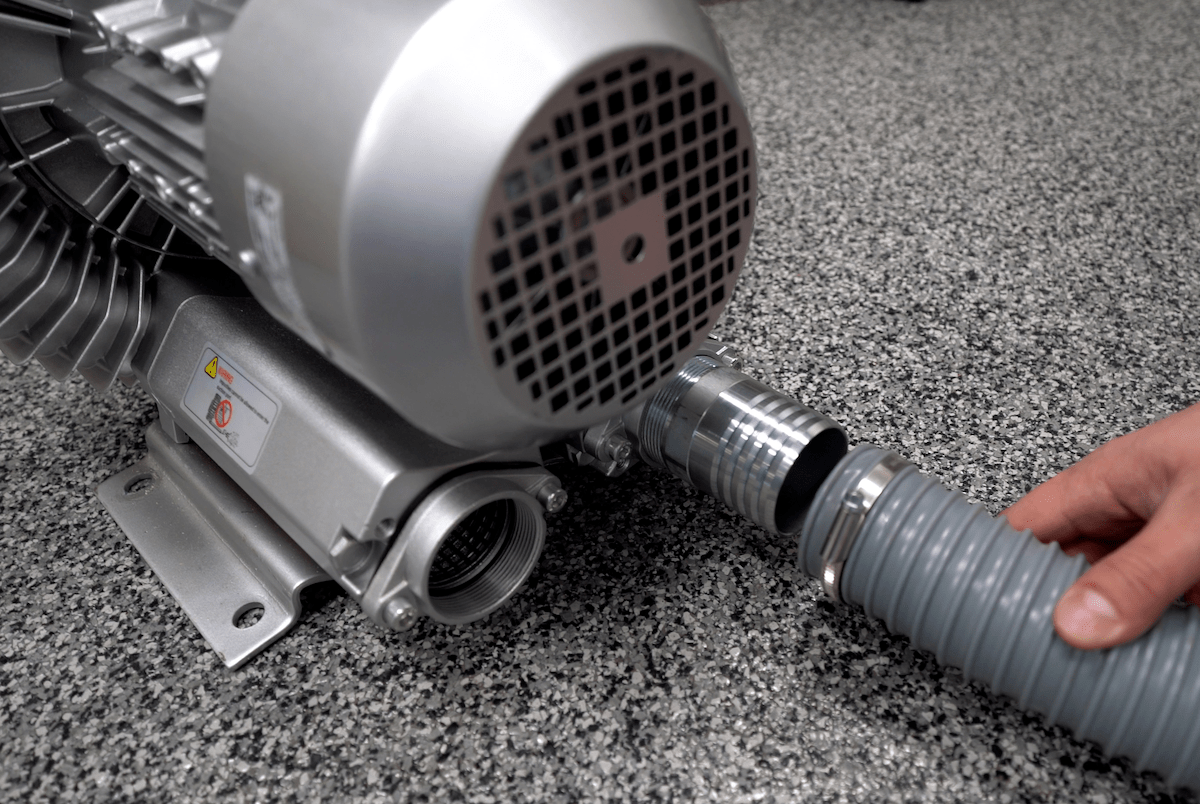

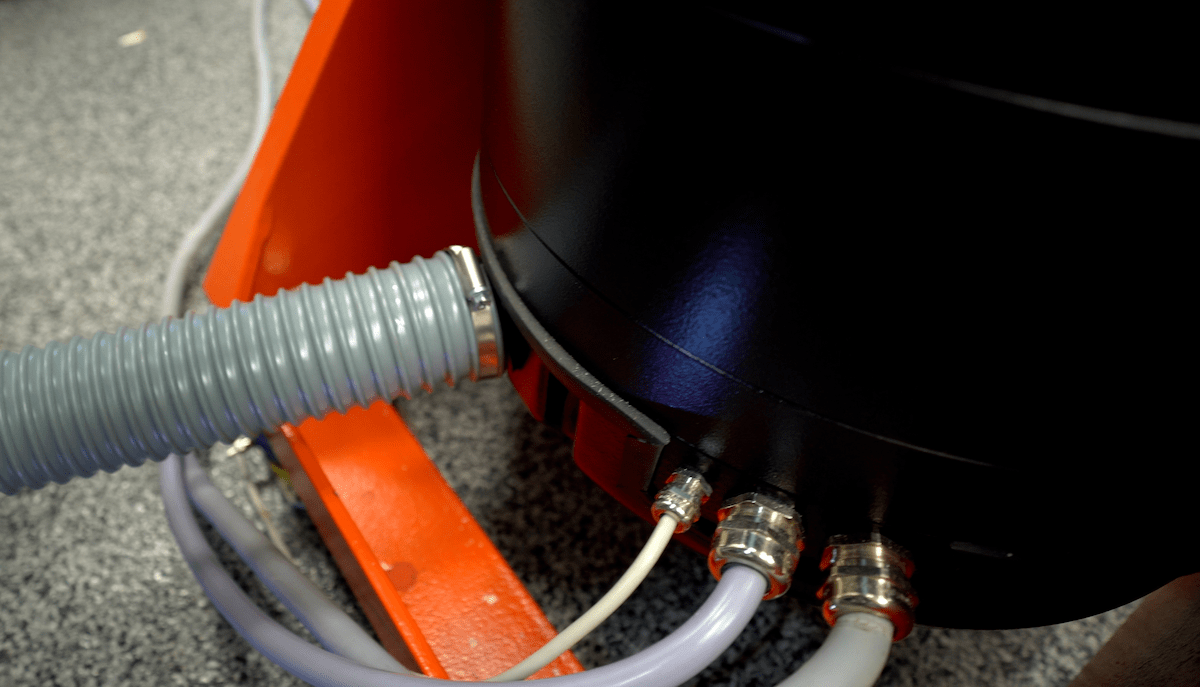

The greatest source of energy consumption in a vibration testing system is the shaker blower. A vibration shaker requires cooling, and the hot air must be evacuated. A blower runs cool air from the laboratory into the shaker and vents the hot air into the lab or outside. This process prompts the air conditioning to run more than normal.

Reducing the time of a vibration test, then, helps to reduce energy cost and consumption.

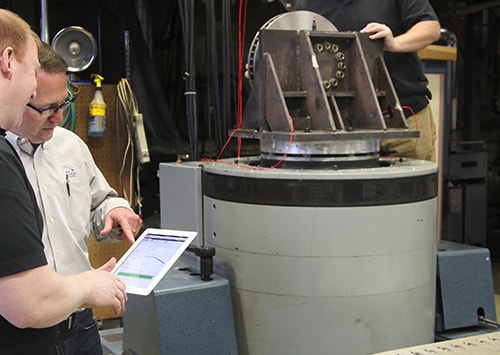

Remote Monitoring Interface

With the Web Server feature in VibrationVIEW, control your vibration shaker test remotely with an iPad or Windows tablet. Use the remote interface to select, start, and stop tests. In Sine, easily change the sweep direction, amplitude, or hold frequency.

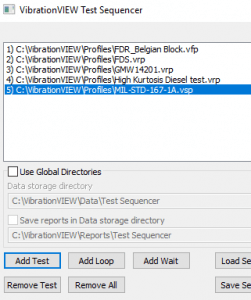

Test Sequencer

Use the Test Sequencer command to build a test schedule and reduce downtime between tests.

The user defines the tests then adds them to the sequence. The tests will be run in the defined order, with each test running for the duration specified within the individual test’s schedule. There will be a pause of approximately five seconds between each test. Optionally, add a “wait for operator” or timed pause to the test.

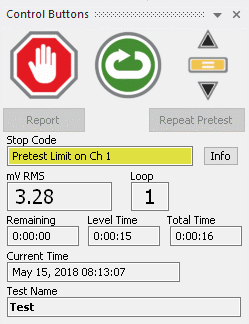

Pre-test Mode

Pre-test mode allows technicians to predict test results without running the full test at level. The control system is stimulated with low-level vibration using a user-defined signal and duration.

After successful completion of the pretest, the technician can determine if the system response is acceptable before running the test at level. The control center provides projected control and demand signals. Any active graphs are also updated with projected system response at partial or full level.

Available in Sine, Random, and Shock.

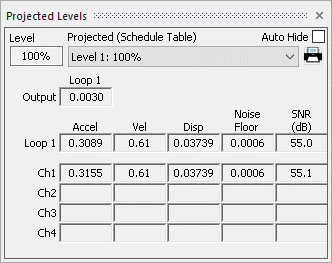

Projected Levels

Display additional diagnostic information about the expected results of a test as it starts and runs. With the projected levels toolbar, technicians can adjust values to complete tests in less time.

For each schedule level, the software projects the output voltage, acceleration, velocity, displacement, and signal-to-noise ratio from the current running level. The projection is provided for each control loop and each input channel.

Available in Sine, Random, Shock, and FDR.