When investing in vibration control hardware, the laboratory engineer or manager largely considers cost and capability—i.e., does it do what I need within my budget? While reasonable considerations, we also encourage test labs to consider their future needs. With technology constantly evolving, a lab will likely need to adjust its system in five to ten years, possibly sooner. The idea of “futureproofing” considers a lab’s present needs and future trends when purchasing equipment to save money.

Test standards evolve, control methods improve, and new technologies emerge—all reasons to keep an eye on future needs. This article will explore the benefits of purchasing “adaptable” hardware and how it can help labs stay ahead in a rapidly changing industry.

Adapting to Industry Changes

Technological advancement is unceasing. The vibration test industry is expected to maintain the pace of product development while the weight, size, and complexity of test items are constantly changing. Test hardware with limited capabilities can hamper productivity and incur significant costs for upgrades and replacements.

Take, for instance, the electric vehicle battery. Within the last decade, test labs have needed to transition from rapid cycle engine testing to shock testing large, heavy battery packs with a high risk of combustion.

Engineers may also require small upgrades when building or scaling up a test process. They may find that a standard random vibration profile under-tests their product, that they need to add more control/response channels, that more power is required to break their product, etc. Comprehensive systems allow engineers to improve their processes with ease.

Benefits of Futureproofing

Investing in hardware isn’t just about futureproofing; it’s also about saving costs in the long run. Hardware with limited functionality requires frequent upgrades and replacements that can quickly add up. Adaptable solutions reduce the need for costly hardware refresh cycles, saving labs time and money. Similarly, it helps labs meet the demands of their workflow.

Beyond performance and productivity, more comprehensive hardware also reduces the frequency of replacements, helping minimize electronic waste.

Futureproofing with Vibration Research

Vibration Research (VR) designs its hardware and software with innovation in mind. Whether upgrading to the latest software or integrating emerging technologies, its systems offer the flexibility and scalability engineers need to stay ahead of the curve.

Expand a System’s Channel Count

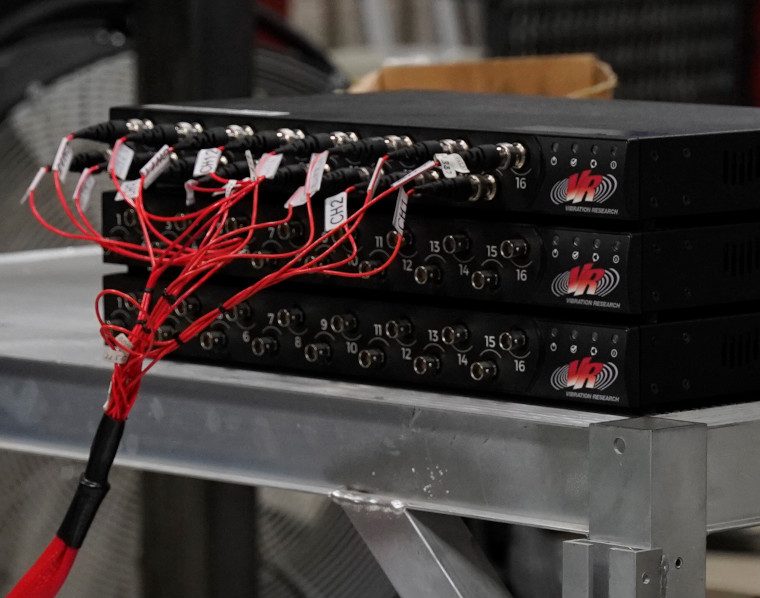

VR hardware units can be stacked up to 512 channels with the VR10500. Customers may want to expand the channel count of their controller for increased test coverage, multi-axis testing, or some other configuration. Channel upgrades do not require a special process, and the customer’s lab can run tests with the expanded channel count within two weeks. Customers only need to connect the new hardware to the network. Additionally, customers can combine/separate individual systems for high-channel-count tests or one-off projects.

VR hardware units can be stacked up to 512 channels with the VR10500. Customers may want to expand the channel count of their controller for increased test coverage, multi-axis testing, or some other configuration. Channel upgrades do not require a special process, and the customer’s lab can run tests with the expanded channel count within two weeks. Customers only need to connect the new hardware to the network. Additionally, customers can combine/separate individual systems for high-channel-count tests or one-off projects.

Legacy Amplifier Upgrade

Vibration control systems are largely moving to digital processing, but many pieces of equipment still rely on analog signals. Most systems convert signals in the digital-to-analog (via a controller) to analog-to-digital (via an amplifier) path. Each conversion risks distortion and noise.

The TruDAC helps maintain a clean signal between a system’s vibration controller and amplifier, providing an isolated digital drive signal. (While the drive path is digital up to the TruDAC, it outputs analog for backward compatibility.)

The TruDAC helps maintain a clean signal between a system’s vibration controller and amplifier, providing an isolated digital drive signal. (While the drive path is digital up to the TruDAC, it outputs analog for backward compatibility.)

The TruDAC also supports a direct digital interface for future amplifier upgrades. As amplifier manufacturers begin to support digital input directly, the TruDAC’s entire signal path will be digital, eliminating unnecessary conversions.

Rent Software

VibrationVIEW test modules are available to rent for short-term needs and activate via an electronic key, giving customers tremendous flexibility. They can use VR’s advanced software licenses for short-term projects or analyze their system’s response to different software during exploratory testing.

VR hardware can also run a temporary key system, which allows customers to stagger their hardware calibration, keeping their shaker running. This feature also saves a lab from expensive downtime in the event of system damage.

Access Support

Vibration Research’s U&SA program extends the value of your purchase. U&SA includes continual extensions to the 3-year full hardware warranty at purchase (for VR9700 and VR10500) and software updates at every release. U&SA customers also have priority access to VR Support, helping test engineers work more efficiently. VR Support can guide customers through the process of setting up a system, troubleshooting test issues, improving their test program, and much more.

Other Examples of Adaptability

- VibrationVIEW systems work with any electrodynamic, servo-hydraulic, or servo-electric shaker and include single-axis, dual-axis, dual-phase, rotational, three-axis, multi-loop/four-post, and seismic control options

- VibrationVIEW software includes many graphical display options, and engineers can use the Math Traces feature to implement custom math operations not defined by the current graph types

- VR software packages can be configured for as many or as few test modules as a lab needs, and it can add more at any time via electronic key

- Sine, random, and shock software include many capabilities outside of standard use, including proprietary innovations that help to solve some of the industry’s most common problems; VR is committed to innovation and is continually ahead of the industry

- VR hardware units function as a vibration controller and data acquisition system