Small components can contribute to the most significant failures, which is why no component should be left to chance when it comes to product development.

Take fasteners, for example. A surprising phenomenon can occur when off-the-shelf fasteners experience dynamic loading conditions. The vibration of working conditions can loosen a fastener, particularly in the case of extreme excitation.

Fastener relaxation is often a gradual process. Engineers performing regular maintenance on a machine may identify the fault before failure occurs, but products passed on to a customer may not undergo these frequent checks. Fastener relaxation can go unnoticed and lead to failure, sometimes catastrophically.

Effect of Resonance on Fasteners

More than one vibration phenomenon can loosen fasteners. For example, vibration running parallel to a fastener’s axis will likely have a different effect than perpendicular vibration. A fastener’s specifications, such as material and thread clearance, will also affect its response to vibration.

Resonance is one of several vibration phenomena that can loosen fasteners. As an example, a test similar to that of the proof-of-concept phase was performed to monitor the effect of resonant frequencies on nut and bolt fastening.

A sine sweep was performed to identify the bracket’s resonant frequencies. A significant resonance occurred in the 51 to 54 Hz range.

Nuts and bolts of varying sizes were fastened to a bracket for an automotive winch mount. The nuts and bolts were not tightly fastened, and they did not have locking features such as lock nuts or thread lock. A vibration test in the 51 to 54 Hz range was run on the bracket with the fasteners.

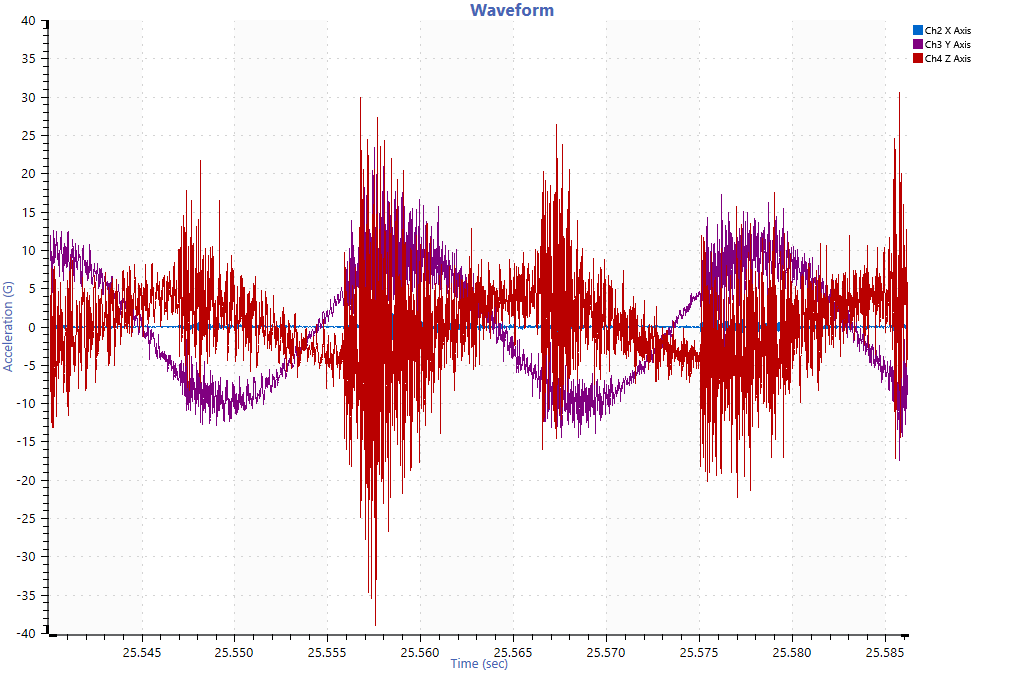

A triaxial accelerometer measured the vibration in the x, y, and z axes. The vibration ran vertical to the bolt, but excitation was recorded in the y and z axes. Likely, the resonance introduced cross-axis vibration whose amplitude was significant enough to unthread (reverse) the nuts.

What Can We Learn from Fastener Response to Vibration?

The phenomenon of fastener response to vibration is well understood, and solutions include:

- Selecting the correct fastener (including thread clearance)

- Using vibration-resistant fasteners, thread lockers, safety wire, or bonding

- Performing regular checks and maintenance

More generally, fastener relaxation points to the importance of replicating the working conditions of a product. Engineers must understand their product’s behavior in the end-use environment early in the product development process and determine if standards like ISO 16047 are satisfactory. The VRU course, Making Sense of Test Data, offers guidance on understanding your device under test and building a good vibration test profile.