The VR10500 vibration controller is a high-powered option for advanced vibration testing, designed to coordinate with high-channel-count and multi-shaker systems. It is an advanced hardware system for complex applications with unique features that continue to set VR apart from the competition.

VR10500 Primary Applications

As a vibration controller and dynamic signal analyzer, the VR10500 is compatible with both the VibrationVIEW and ObserVIEW software packages. The primary applications of the VR10500 include:

- 16 Channel System

- Up to 512 Input Channels

- Multiple Shaker Systems

- Up to 6 Outputs (4 Analog and 2 Digital)

- Controller & Analyzer Combination

- Advanced Controller Configurations

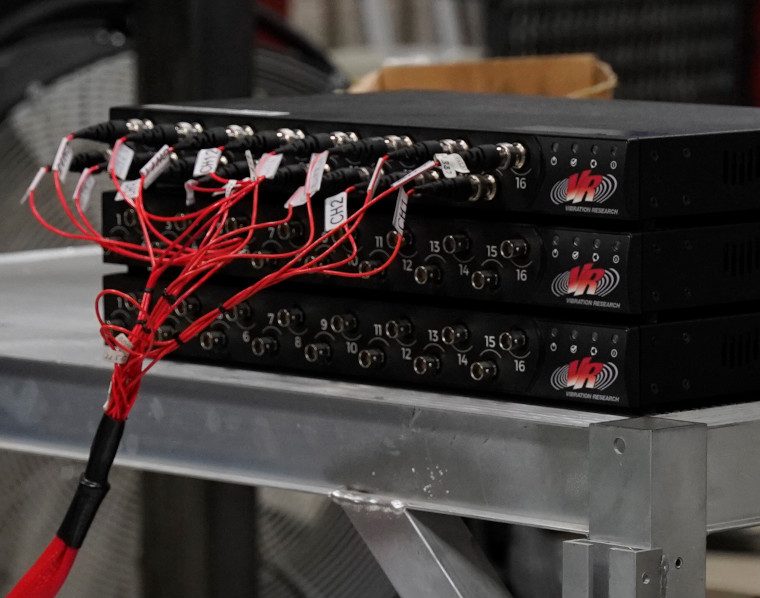

High-Channel-Count System

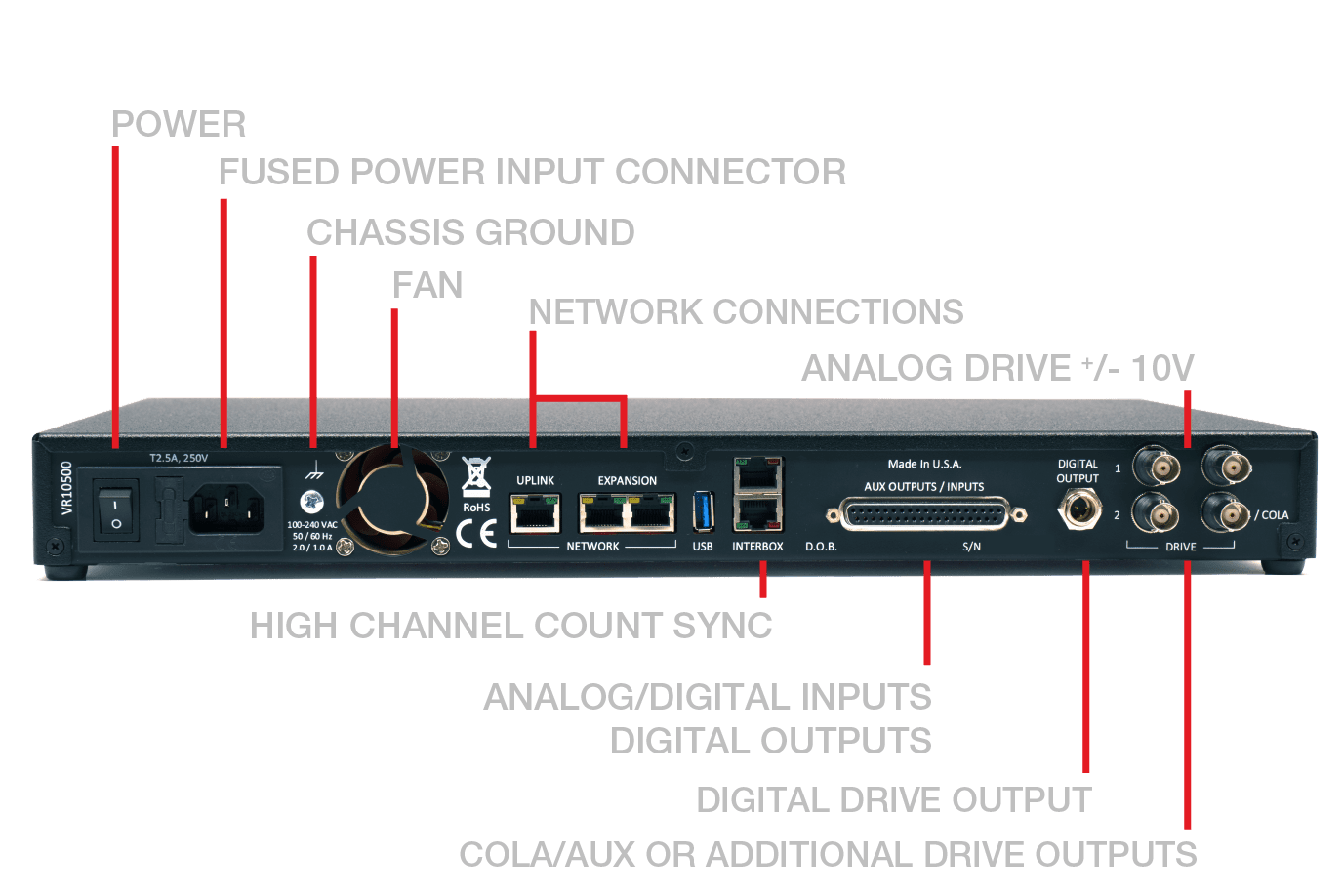

The VR10500 has 16 analog inputs, and systems can be combined to a total of 512 channels. The hardware supports configurations of 8, 12, 16, 20, 24, 28, and 32 channels. After 32 channels, the channel count increases by increments of 16.

All 512 inputs can be used simultaneously and at the same sample rate, and any combination of channels can be used to create an optimal control or limiting solution. The 512 channels are fully functional and can be used at the maximum 256kHz sample rate.

A higher channel count may be beneficial or required for advanced testing situations for application-based, high channel count systems and large or complex structures like wings, rockets, missiles, satellites, full vehicles, etc.

Six Outputs from a Single Controller

For multiple shaker systems, a single VR10500 controller has the potential for up to 6 control outputs: 4 analog control outputs and 2 digital control outputs. Engineers can drive two shakers in phase, multiple shakers with independent output loops (without phase control), and three-axis systems without cross-coupling or correlation.

With the VR10500, the outputs are generated from the same hardware, which provides more power and control. It also provides the opportunity for further software development and implementation of additional control methods for multi-shaker and multi-axis control.

Digital Drive Output

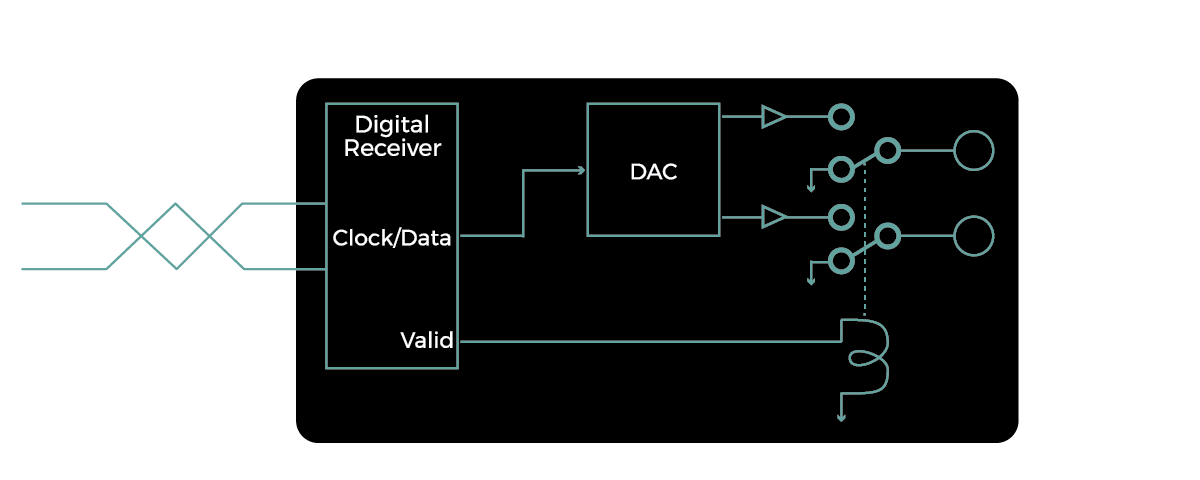

The VR10500’s digital drive output is unique to any vibration controller. The interface supplies two additional drive signals that can be used with the four analog drive signals or separately as two remote drive outputs.

The digital output removes the analog link between the shaker and the amplifier to minimize the effects of ambient noise picked up between the controller and amplifier. No other controller on the market has this capability.

The digital control output also improves connection safety. If an analog connection between the controller and amplifier is broken or damaged while the test is running, it can create a significant transient spike that could damage the shaker. A digital link simply breaks and then shuts down.

This output also breaks the ground path between the controller and noisier amplifiers/shaker systems to eliminate one of the potential ground loops in vibration testing systems.

Currently, the digital control output requires a conversion box to convert the digital signal to analog before reaching the amplifier. After a solution has been developed, VR plans to work with amplifier companies to implement the conversion as a new standard in shaker amplifiers.

Targeting Future Amplifier Technology

Vibration Research’s TruDAC Digital Output is a stand-alone unit that can be added to a VR10500 or VR9700 system.

Vibration Research’s TruDAC Digital Output is a stand-alone unit that can be added to a VR10500 or VR9700 system.

A digital control outputs device serves several purposes:

-

- Detects disconnected and broken cables between the amplifier and controller

- Supports longer cable lengths between the amplifier and controller without control signal degradation

- Breaks the ground path between the amplifier and the controller drive, eliminating a common source of noise

Additional Features

Additional features of the VR10500 include:

- Up to 16 Channel Sine-on-Random Tone Response

- Integrated Network Switching

- Tachometer Inputs

- Higher Voltage Digital I/O

- Digital Control Output

- Quad-Core Processor

Remote Inputs/Outputs

The remote input on the VR10500 has the additional capability to support a dual tachometer or a single quadrature tachometer. This feature is most significant when using the controller as a dynamic signal analyzer. It also has a timestamping option for remote inputs.

The remote output internal voltage is 5V, but engineers can connect an external 24V power supply and manipulate the voltage through the digital output.

New Software Development

The increased processing power and channel count of the VR10500 create new testing opportunities, and the improved user interface allows for high channel count configuration. There are also many opportunities for new software features. Software development for the VR10500 is currently underway. If your team would like to be a part of the development process, please contact your sales representative for more information.