Article Overview

-

- What a shaker fixture is and its role in vibration testing

- Key design principles for effective fixtures

- Importance of fastener selection and maintenance

- Fixture design checklist

What is a Shaker Fixture?

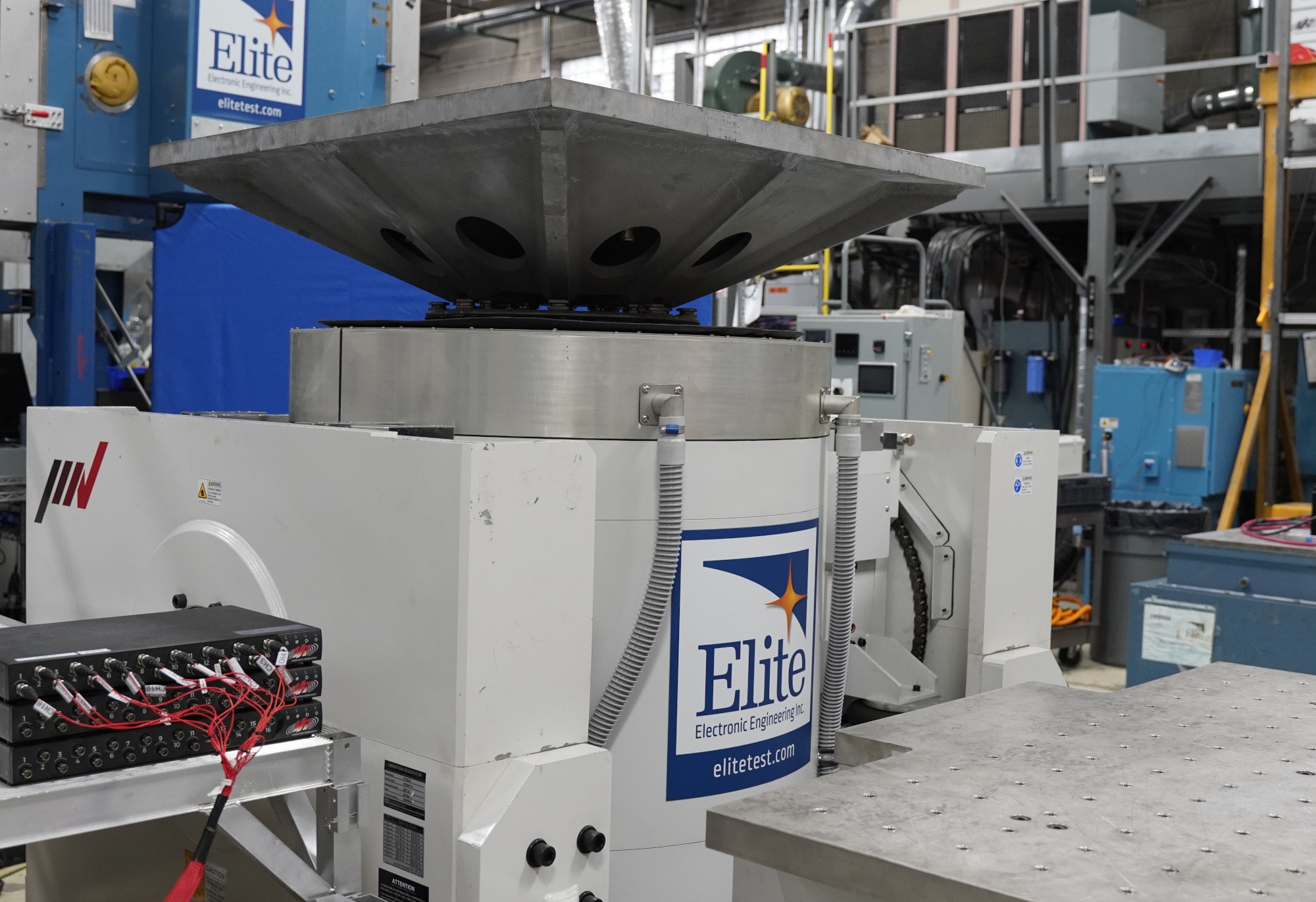

In vibration testing, engineers use shaker fixtures to securely mount a test article to a shaker head in its intended orientation. Shaker fixtures provide mechanical support, and well-designed fixtures are often necessary for reliable vibration test results.

Engineers use fixtures to mount the test article in the required orientation, distribute load, and adapt the test article to the shaker interface.

Shaker Fixture Design Examples

For example, a shaker should vibrate in the vertical direction when testing a military vehicle computer with road-like vibrations. With a shaker fixture, the test engineer can mount the rugged computer to the fixture in a vertical orientation (Figure 1). If the computer was mounted horizontally, the direction of the vibration test would be perpendicular to real-world operation.

Car electronics face a similar predicament. The instrument panel, audio controls, and navigation system must be attached to the shaker in the same orientation, including tilt, as in the vehicle (Figure 2). In fact, many devices should be oriented in the same manner as their end use for realistic testing.

Figure 1. A rugged military vehicle computer mounted on a fixture in the orientation of its end-use environment.

Figure 2. An auto head unit mounted on a shaker.

Do I Need a Shaker Fixture?

In most cases, a vibration testing setup requires a shaker fixture. The alternative is mounting the test item directly to the shaker head, which introduces several potential issues:

- Shaker may not support the required axis of excitation

- Base of the test article may not align with the shaker

- Direct bolting may introduce uneven force distribution

- Overhanging test article may introduce resonances

- Heavy or unbalanced loads may cause off-axis forces

- Consistent mounting may be difficult

Unless the test article matches the shaker interface directly, a test setup will likely necessitate a fixture for accuracy and repeatability.

Tips for Shaker Fixture Design

A well-designed shaker fixture provides an accurate response, minimizes unintended resonances, and protects the test article and equipment.

Fixtures should transmit vibration energy from the shaker to the test article without amplifying or attenuating certain frequencies. It should not resonate within the test frequency range, nor should it dampen the vibration energy.

A fixture should not have any motion of its own in any axis. The fixture must be properly mounted to the shaker table, and no parts should be free to move or vibrate.

Additionally, the fixture must be designed and constructed so it is not damaged during testing. However, this reliability cannot be achieved by over-engineering a massive fixture. Additional mass causes the shaker to work harder and limits its responsiveness to changing control signals.

Fastener Response

Shaker fixtures are often bolted down. Fasteners are susceptible to vibration, so consider using vibration-resistant fasteners, thread lockers, safety wire, or bonding and make sure to perform regular checks and maintenance.

Summary

An optimal shaker fixture securely mounts the DUT in its proper orientation and provides mechanical support. A fixture must accurately transmit shaker inputs without inducing unwanted resonances or motion, and its mass must not affect shaker performance. Attention to fastener integrity and regular maintenance helps prevent fixture degradation over time. By combining these design principles, engineers can incorporate fixtures that facilitate efficient testing.

A well-designed shaker fixture has the following characteristics:

-

- Mounts the DUT to the shaker system in the orientation of end-use

- Transmits the forces from the shaker to the DUT without resonances or interference

- Serves to quickly mount and test multiple samples of the DUT

- Has minimal mass so the shaker can function with minimal force

- Performs many tests without sustaining damage

- Does not have any independent motion in any axis