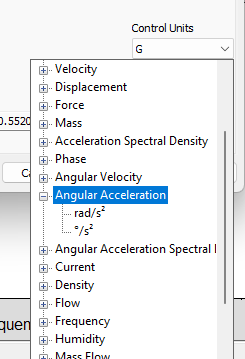

Control rotational/angular acceleration with multi-axis shaker control, which enables a 360-degree movement with plate and tilt adjustment.

Control rotational/angular acceleration with multi-axis shaker control, which enables a 360-degree movement with plate and tilt adjustment.

The VibrationVIEW software can measure and control vibration on rotary systems with rotational, vertical, and angular vibration modes.

Vibration Control Hardware

VR9700 I/O Unit

Vibration Research’s high-powered control hardware for vibration and shock testing. Scalable to 128 channels and compatible with all electrodynamic and servo-hydraulic shakers. Features include up to 256 kHz sample rate and 2 outputs.

VR10500 I/O Unit

Vibration Research’s high channel count control hardware for vibration and shock testing. Scalable to 512 channels and compatible with all electrodynamic and servo-hydraulic shakers. Features include up to 256 kHz sample rate and 4 outputs for multi-shaker testing.

Shaker Compatibility

Vibration Research hardware works with any electrodynamic, servo-hydraulic, or servo-electric shaker and includes single-axis, dual-axis, dual-phase, rotational, three-axis, multi-loop/four-post, and seismic control options.

Tripod Shakers

Engineers can define the geometry of a 3-axis translational-only tripod system in VibrationVIEW. The software supports linear and rotary configurations. The VR10500 outputs connect to the valve controller inputs and use tripod dimensions and limits as system limits.

Why Rotational/Angular Acceleration Control?

Engineers use rotational/angular acceleration control to simulate rotational and asynchronous motion and measure the response of components to these modes. If the device under test has a rotational or angular mode of vibration, then a rotary shaker may be suitable for testing.